Get Directions

Get Directions

Get Directions

Get Directions

Krone BiG X 680 | 780 | 880 | 1180

|

OptiMaize brings full flexibility to all KRONE BiG X harvesters, allowing them to produce any type of chop length livestock farmers and Biogas producers call for. MaxFlow and Biogas drums are available with various numbers of blades and combine with matching KRONE conditioners to deliver perfect 4-30 mm (0.2"-1.2") chops and the most intensive treatment. The BiG X offers this wide range of chops without operators having to swap or refit the chopping drum – simply by reducing the cutting frequency with the help of VariLOC. |

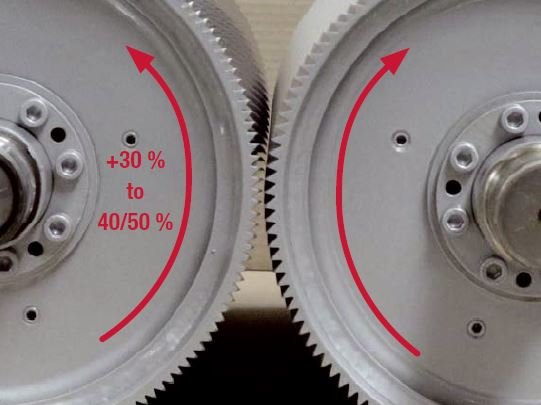

OptiMaize S: Maize that is harvested to fuel biogas plants is chopped to very short lengths. Depending on moisture levels, chops of 4 mm to 7 mm lengths have been found ideal for this application, because shorter chops make the energy readily available to the methane producing bacteria in the fermenter thereby increasing gas yields. The KRONE forage harvesters use a Biogas drum with 40 or 48 blades to harvest biogas maize. Alternatively, OptiMaize S results can also be achieved with the 36 blade MaxFlow drum. For good fermentation, the leaves and stalks are subsequently fractured and the kernels destroyed by a KRONE corn conditioner with 123/144 teeth and rotors rotating at a 30 % speed difference. |

OptiMaize M: Grass based rations for beef bulls and dairy cows which consist of up to 40 % of maize should be made up of 8 mm to 10 mm (0.3" to 0.4") chop lengths. This length of cut and an appropriate conditioning intensity avoids lack of fibre in the ration. OptiMaize M chopping quality is achieved by the MaxFlow drums with 36 and 28 blades. The ideal conditioner is the KRONE corn conditioner with 123/144 teeth whose speed differential can be increased from 30 % to 40 % or 50 %. |

OptiMaize L: Chop lengths of 11 mm to 19 mm are ideal for dairy feed rations where the percentage of maize is about 60 %. Rumens require silage maize that is reach in fibres. The OptiMaize L chopping quality is achieved by the KRONE MaxFlow drums with 28 or 20 blades. The complementary conditioner for these drums is the assembly with 105/123 teeth.The speed differential on these rollers can be increased from 30 % to 40 % or 50 %. |

OptiMaize XL: The maize in dairy feed rations made up of more than 80% by maize and that do not contain sufficient quantities of grass and feed straw should be chopped to 20 mm to 30 mm lengths to avoid lack of structure in the feed. The ideal drum for long chops is the MaxFlow drum with 20 blades which is complemented by the KRONE OptiMaxx roller conditioner with 105/123 teeth and 30%, 40% or 50% speed differentials. |

The intake System

Chopping drum

VariStream

VariQuick

The OptiMaxx roller conditioners

StreamControl

|

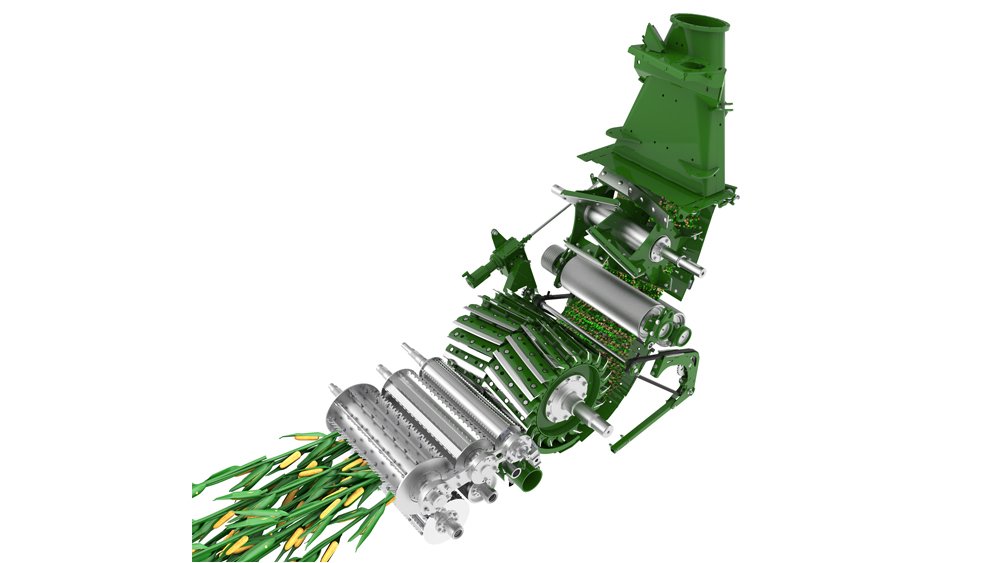

The crop flow

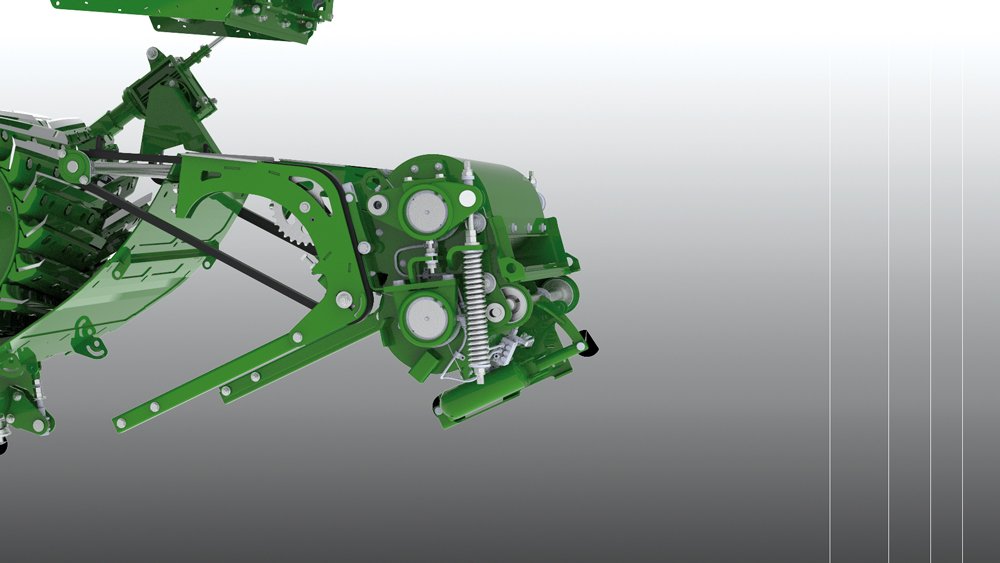

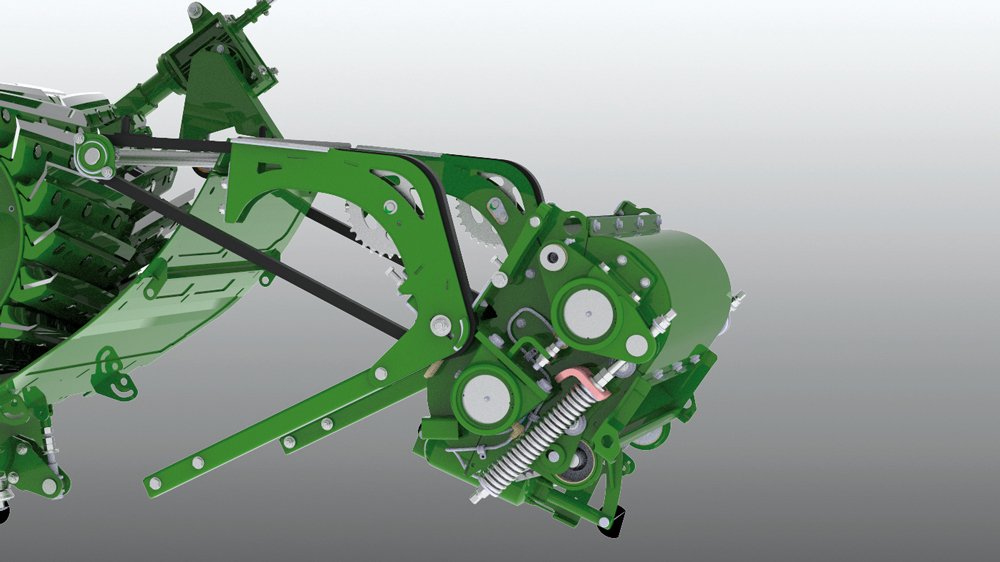

Its innovative technology makes the BiG X a superior chopper with respect to performance and quality. Chopping lenghts can be set to individual requirements by adjusting the speeds of the intake rollers and using different numbers of blades on the chopping drum. Highest through puts are implemented by the spring-loaded floor underneath the drum and a spring-loaded accelerator backplate which guarantee a continuous crop flow. |

Its innovative technology makes the BiG X a superior chopper with respect to performance and quality. Chopping lenghts can be set to individual requirements by adjusting the speeds of the intake rollers and using different numbers of blades on the chopping drum. Highest through puts are implemented by the spring-loaded floor underneath the drum and a spring-loaded accelerator backplate which guarantee a continuous crop flow. |

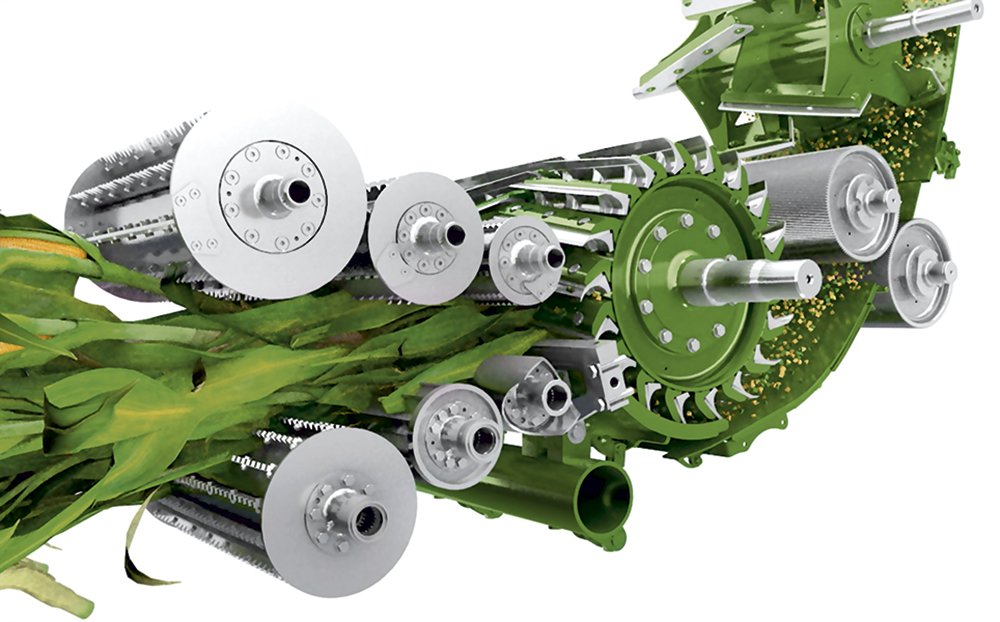

Versatile and flexible: Six pre-compression rollers and the 820 mm gap between the leading roller with metal detector and the counterblade not only enhance pre-compression but also protect the blades better against metal objects, even at high-speed intake. The hydraulic drive in combination with AutoScan adjust the chop length automatically to the maturity of the crop. |

Across the full width: The leading bottom rollers are studded with sensors across the full width which detect any metal that is about to enter the machine. The large throat volume makes for highest throughputs. The robust drives withstand the highest strains. |

Folding open: Operators can fold the intake system forward to gain access to the chopping drum and the counterblade. |

|

Matching the drum dimensions to the forager model and choosing the optimum number of blades not only boosts machine power but also makes the forager more flexible to suit more applications. The wide range of OptiMaize drums that are available for BiG X deliver top-quality chops in versatile applications anywhere in the world. |

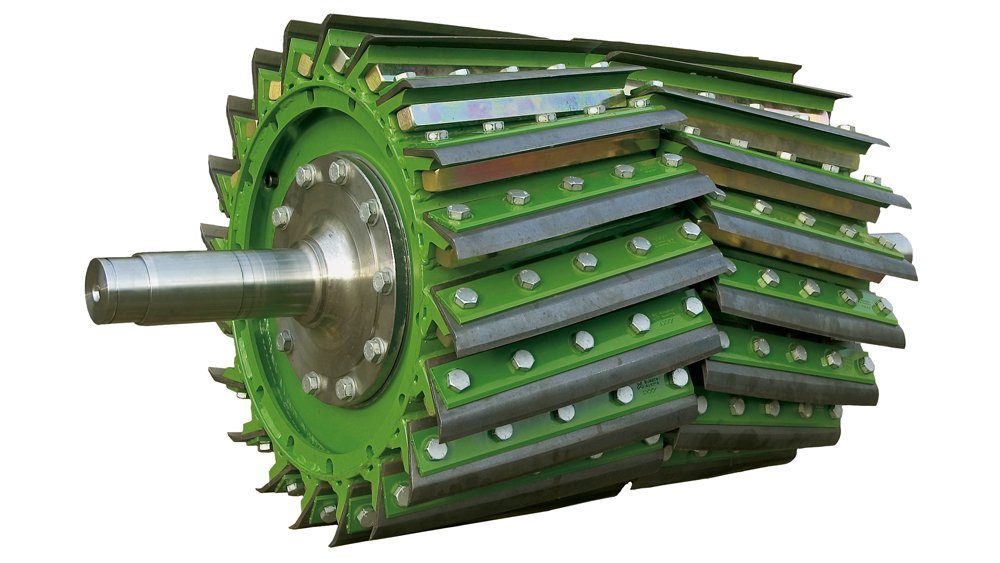

The material is pulled over the blades: The blades on the KRONE chopping drums are arranged chevron-style and at an angle of 11° relative to the counterblade. This arrangement makes for a continuous crop flow, extremely quiet running and maximum efficiency. |

Cutting Edge: To ensure a good quality cut, the blade and the counterblade must be set to the correct gap. The blades are quick and easy to align using the eccentric plate. |

Protected drum body: Protected drum body The carrier bars of the blades have another function besides: they protect the closed drum from wear. |

40-blade drum for OptiMaize S: With its higher throughputs and lower fuel consumption per tonne of chopped maize, the 40-blade Biogas cylinder pays for itself in no time. The extremely short chops of 2.5 mm to 15 mm ferment at a higher rate and increase the gas yield, allowing farmers to produce more biogas from a smaller fi eld. |

High frequency of cuts: 40 blades can achieve an impressively high cutting frequency. So the Biogas drum cuts harvesting time and increases throughput – even when producing short LOCs. |

48-blade drum for OptiMaize S: Delivering a 20% higher cutting frequency than the 40-blade drum and a theoretical LOC ranging from just 2 to 12 mm, this Super Biogas drum with 8 blades produces an even shorter chop, Boosting gas yields and throughput at the biogas plant even further and reducing fuel consumption per tonne of crop with the same LOC. |

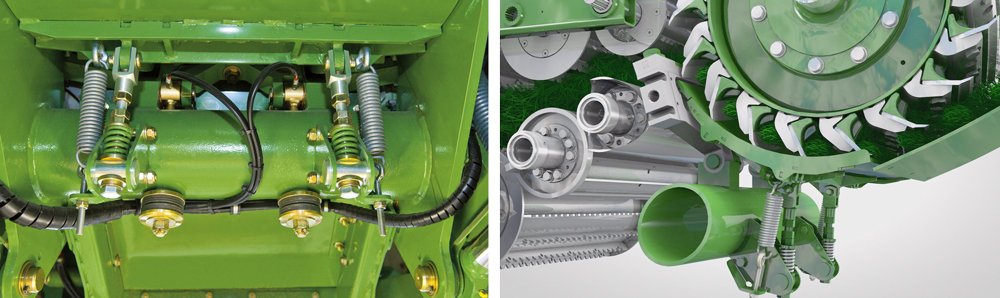

Every single kernel must be cracked to achieve an optimal digestibility. These user demands are perfectly met by the new OptiMaxx 250/305 roller conditioners with their slanted teeth, a new KRONE development.

|

Perfect conditioning: The new OptiMaxx roller conditioners have their teeth slanted at a 5° angle.This slant produces a clearly higher shearing effect and perfect conditioning of the crop which receives a very intensive treatment both length- and sideways. |

Maximum intensity: The two toothed rollers operate at a 30 % speed difference. This standard difference can now increase to 40-50 % to deliver 100 % conditioning and fracturing of long chops as produced by OptiMaize XL. |

The top-standard OptiMaxx 250

|

OptiMaxx 305 for maximum output

|

|

VariQuick is the system that allows operators to converse BiG X very quickly from maize to grass. A chain drive (electric option) moves the corn conditioner out of or into the crop flow. If the corn conditioner is not used for longer periods of time, you can lower it and remove it from the machine by pulling it out to the side. |

Easy to transport: After the transport wheels are fitted without tools, the corn conditioner pulls out to the side and is conveniently rolled to the shed. |

Corn Conditioner in park position: The chain drive moves the corn conditioner out of the crop flow and into its parking position so work can temporarily continue in grass without any major changeover. |

Removing the Corn conditioner: If the corn conditioner is not used for an extended period of time, you can lower it with the help of the chain drive and then remove it. |

KRONE VariStream comprises a spring-loaded floor beneath the chopping drum and a spring-loaded back plate in the crop accelerator housing.The system ensures blockage-free and smooth operation, even in varying volumes of crop. The technology allows operators to utilise the forager to its limit and use less fuel per hour. |

Best quality of chop in inconsistent crop flows: The spring-loaded chopping drum floor is connected to the anvil of the counterblade at the front. As these are readjusted, the gap between the blades and floor does not change. So any movement of the spring-loaded chopping drum floor that compensates for an inconsistency in the crop flow will not affect the quality of chop. |

A tight crop stream: The spring-loaded backplate on the crop accelerator ensures maximum throws and targeted fills in all conditions. |

The crop throw is controlled from the cab by adjusting the door in the backplate on the crop accelerator. This way, operators can adjust the throw quickly to the current filling situation. As the accelerator needs less power to cover a short distance, the operator can free up engine output and use it for chopping and higher throughputs. |

Variable throws: The crop throw is controlled via the hinged flap on the backplate of the accelerator. For a short throw, the flap moves out of the crop flow, so there is little contact between the crop and the accelerator. For a long throw, the flap moves into the crop flow, so there is more contact between the crop and the accelerator. |

Short-distance throws: Filling trailers that are travelling alongside the forager does not require a powerful throw. Instead, in these situations engine output can be freed to boost the chopping capacity. |

Long-distance crop throws: With the trailer following behind, the crop stream needs to be ejected from the spout at a higher speed. A strong, tight stream is needed to cover the long distance over the tractor to the trailer. |

The multi-coupler system of the BiG X allows operators to couple headers fast, easy and dependably from the seat, reducing changeover times when preparing for road travel or different crops. This way, more time is spent on productive work. |

Large capacity: Working at widths of 3 m and 3.8 m, the EasyFlow pick-up on a BiG X gives the machine plenty of intake capacity. Depending on the swath width and your working speed, you can vary EasyFlow rpm steplessly from the cab or have it adjusted automatically to the current forward speed without the operator having to interfere. Its curved round steel bracket gives the Header the flexibility to pivot through a large angle and makes for easy attachment and removal. |

KRONE XDisc is a versatile direct cut header that cuts whole crop silage cleanly and without losses. The powerful and massive 900 mm diameter feed auger on the XDisc 620 works trouble-free even in dense and tall crops. |

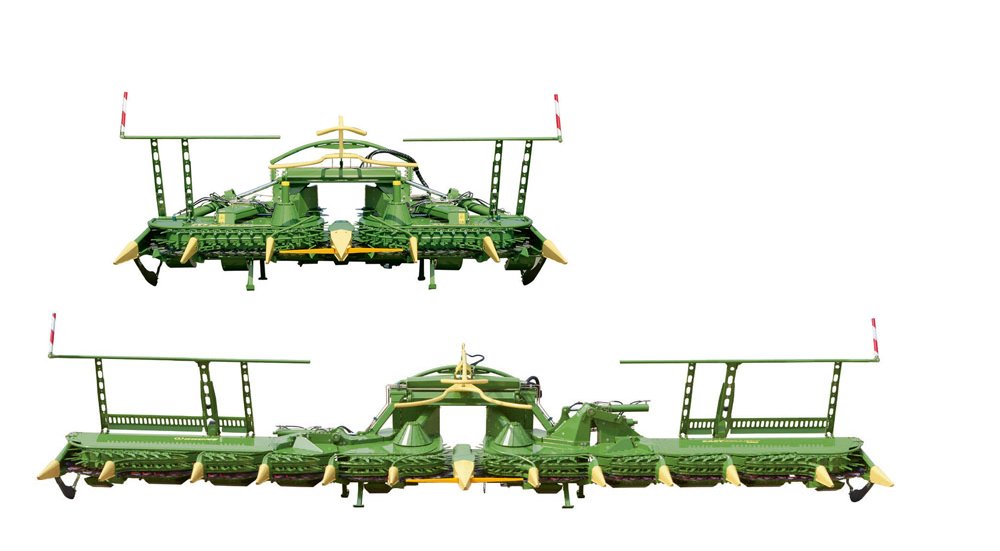

High-power & high-efficiency: Working at widths of up to 10.5 m (34’5”), BiG X features the widest variable-row width header in the world. The endless collectors feed the stalks to the middle where they are turned through 90° and pulled in lengthwise. |

Three work widths: The new XCollect header is available in three work widths: 600-3: 6 m (8 rows), 750-3: 7.5 m (10 rows) and 900-3: 9 m (12 rows) The three-section headers work to the well-proven EasyCollect collector principle. The XCollect splits the action of cutting and feeding into two separate processes. |

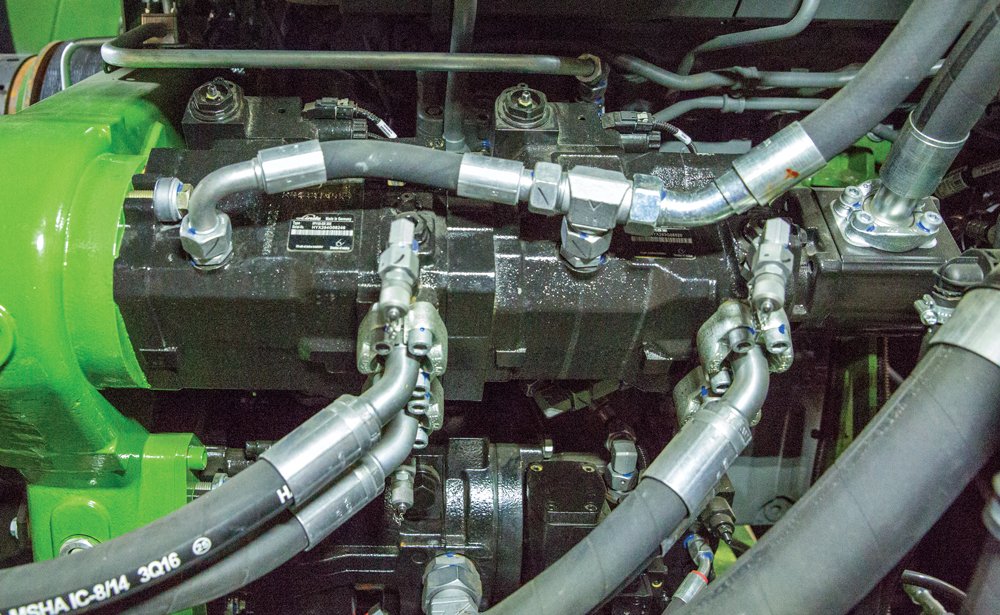

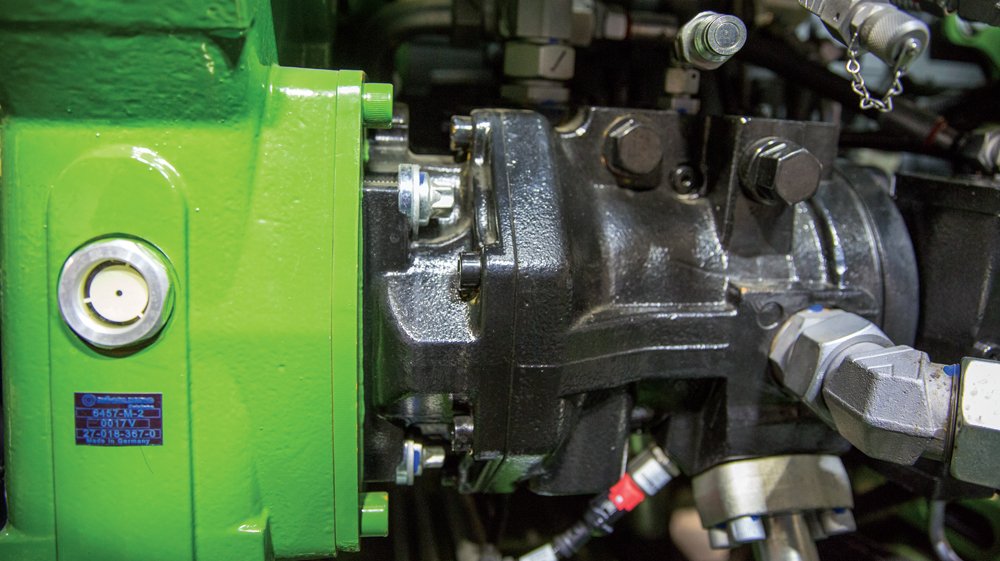

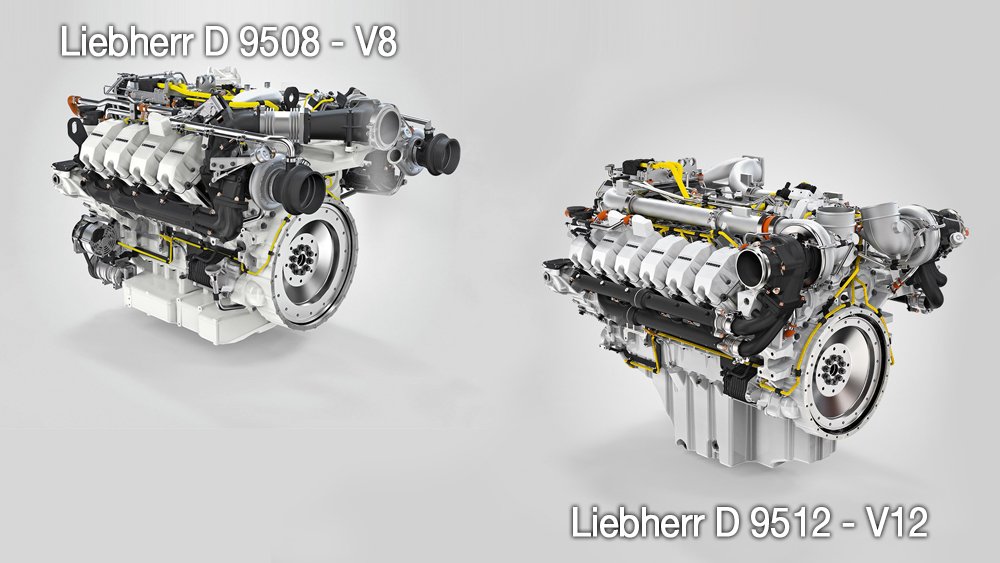

Advanced Common-Rail engine technology from Liebherr suggests superior outputs and fuel economy. The engines stand out for optimum torques, quiet running, superb fuel economy and high efficiencies. |

Wheel motors offer greater productivity and a higher level of automation and operator |

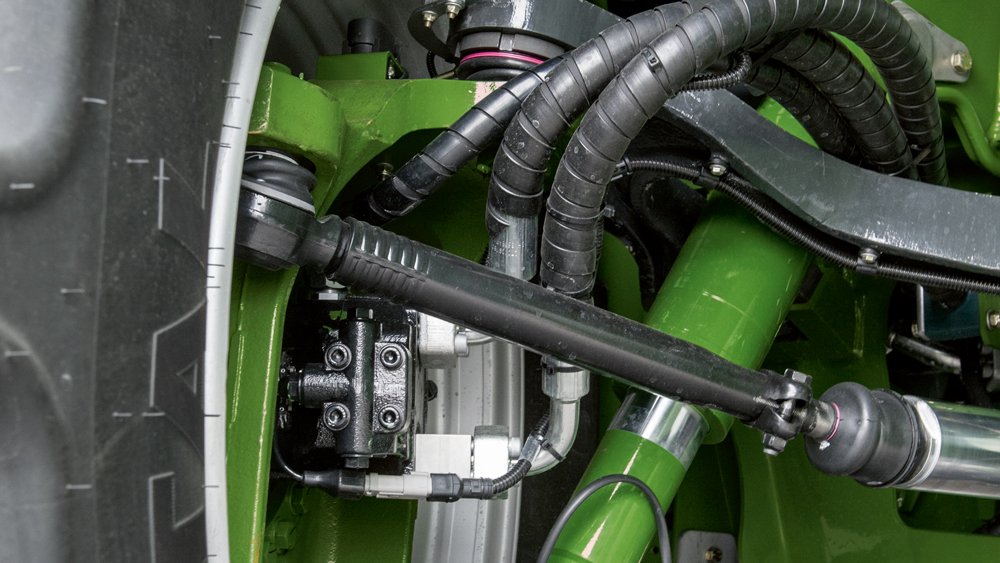

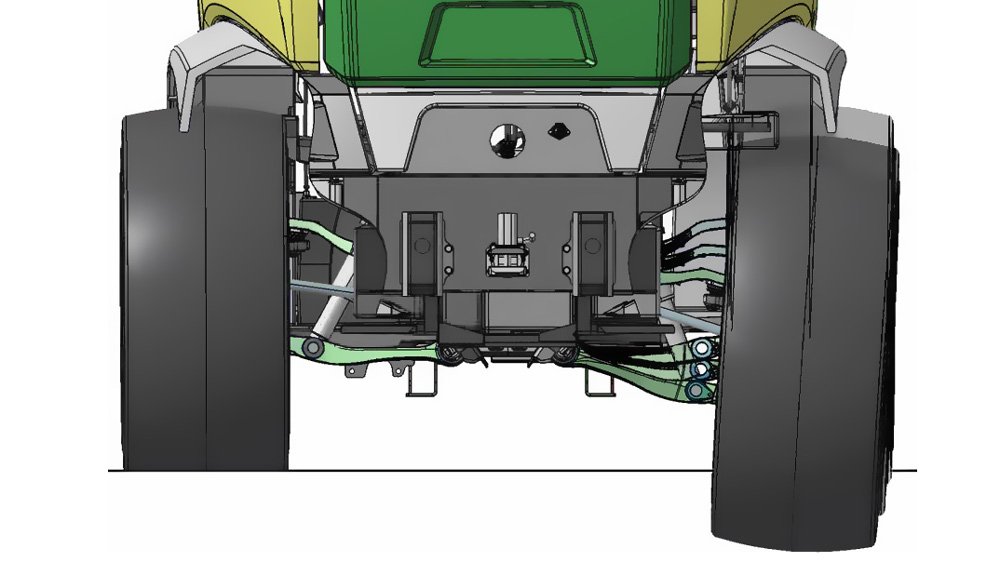

4WD: BiG X 680/780/880 are available with hydraulic wheel motors on all four wheels as an option. |

Good build: The use of hydraulic wheel motors results in a very generous ground clearance and creates room for a larger diameter chopping drum and also leads to a more even weight distribution. |

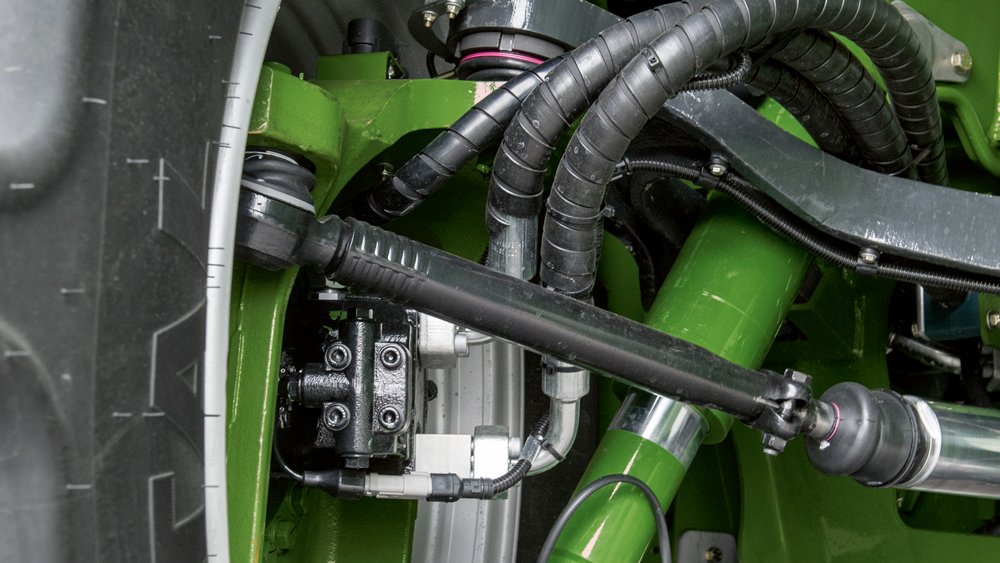

Great maneuvrability from independent wheel suspension: The independent wheel suspension system off ers plenty of room for steering so that even when clad with massive tyres BiG X remains a very nimble machine in undulating terrain. In addition, the suspended system provides maximum operator comfort. |

Extremely agile: Using wheel motors increases the steering angle to a generous 50° for tightest turns and perfect match-ups after headland turns |

In the heat of harvest operators often work into the night.To ensure best visibility |

Day and night: BiG X can take up to 23 optional LED work lights which make field work safe and effective even during those night shifts. |

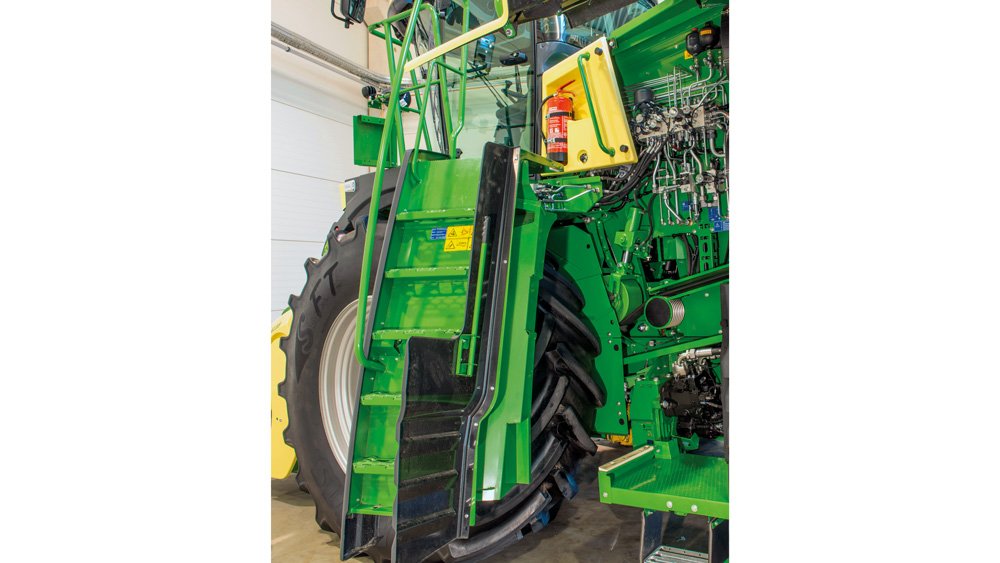

Moving the ladder out of the way: The access to the cab is easily moved out of the way to give convenient access to all nearside service points. |

Automatic lubrication: The auto lubricator and its large grease reservoir allow operators to spend less time servicing and maintaining the machine. |

Easy access: The hoods open wide and the rear mudguards give perfect access to all assemblies. LEDs are in place for easy service and maintenance even in poor light conditions. |

Useful storage space: The nearside storage compartment at the rear boasts a pivoting table which accommodates the toolbox for convenient use. |

Easy to get at: The batteries are stored in the storage space on the right side of the machine where they are in easy access. |

It takes a comfortable working place to stay fit and alert during those long working days. The spacious Silent Space cab offers such an ideal environment. Providing generous space to the operator and a passenger, it provides a fully air-conditioning and an absolutely functional working place. The exclusive LiftCab offers an unprecedented panoramic view from a height of up to 70 cm. |

A scissor lift for the cab: The cab is mounted on a scissor lift which raises and lowers the cabin to any position – infinitely variably and within a few seconds. The area under the cab floor is shielded to prevent of dirt and debris. |

Superb visibility: If the BiG X is specified with a LiftCab, it will be possible to raise the complete cab to any height up 70 cm. From the raised position operators enjoy a full overview of the tall stands and can easily monitor the filling processes. As another advantage, the raised cab increases the distance between the operator and the chopping assemblies thereby reducing the noise level at operator’s ear. |

Less operator stress – more peace of mind: Harvesting high-yielding maize crops, forager operators often are driving up towards an up to 4 m high wall of crop all day. The cab lift allows them to raise their seating position and enjoy a clear view of the field, reducing fatigue and helping them concentrate on the machine and spot any hazardous situations more easily. |

Everything in control: High-sided trailers can be a problem for the forager operator who has to determine when the trailer is filled to capacity. In this situation, raising the cab by 70 cm is a big help. Whether the trailer is travelling alongside or behind the forager, the operator has always a clear view of the load area and can ensure optimum fills. |

Panoramic view: High side windows and slim posts give the operator an unobstructed 360° view of all processes. |

Sun blinds: Sun blinds are available for the side and rear windows to protect you from the sun and heat. |

Perfect visibility: Now matter the conditions – rain or dust –BiG X operators always enjoy a clear view thanks to three optional wipers on the front window, two on the side windows and one on the rear window. All wipers have water jets. |

Clear concept: The heating system and the air conditioning are operated from the terminal above the front window. The Follow- Home function lights your way as you get down from the cab. After you switch off for the night, some headlights stay switched on for several minutes, allowing you to fi nd your way safely. |

The cockpit: All controls including the joystick, the screens and the terminals are designed to ergonomic standards and in easy reach from the operator seat. |

Chopping as short as necessary: A photo-optical sensor in the middle of the maize header measures the maturity of the plant and automatically adjusts the length of cut. Green maize is cut to longer chops to get more structure and reduce effluent in the clamp. By comparison, dry and brittle maize is cut to short chops to increase compaction. This way, AutoScan eases the load on the operator and reduces fuel consumption by optimizing the length of cut. |

Lift speed: After the operator selects the desired engine load, ConstantPower automatically matches the forward speed to the current stand and yields, easing the strain on the operator and improving fuel economy at maximum throughput. In combination with AutoScan, this system takes the overall quality of chop and machine performance to a whole new level. |

The EasyLoad auto loading system in tandem with the camera-based 3D image analysis make it so much easier to fill low- or high-sided trailers running alongside or behind the harvester. The system controls the open/close spout and the rotate left/right functions and allows operators to select one of several filling strategies. Monitoring all functions from the in-cab screen, operators are more at ease. |

Intelligent precaution: The optional RockProtect system provides intelligent protection from damage by stones as it fully automatically halts the pre-compression rollers within milliseconds after a stone is detected. The sensitivity of the system is set by the operator. |

Auto guidance: Every BiG X machine is ready to accept various ISOBUS guidance system brands. On the move, the operator activates autoguidance from the KRONE joystick. |

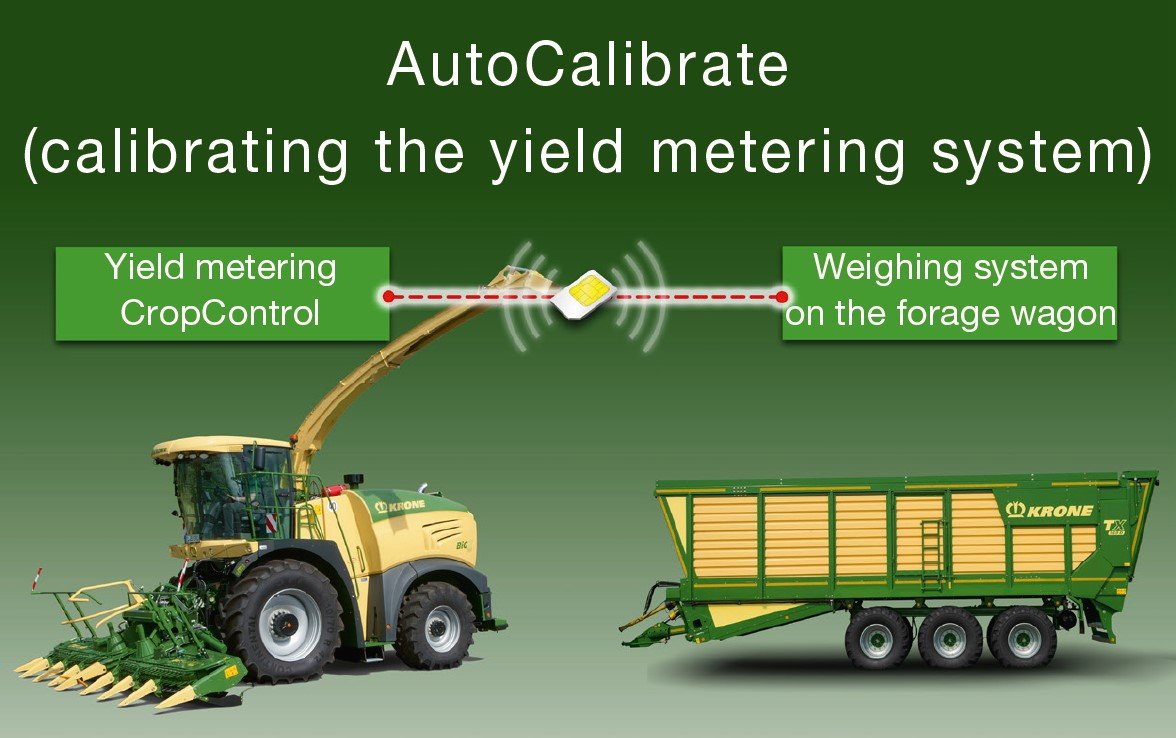

Measuring yields per field: The optional KRONE CropControl yield metering system measures the volume of crop harvested per field quickly and accurately at the touch of a button. The system allows operators to document meticulously all yield information in all fields harvested. |

Convenient weighing: AutoCalibrate is the remote calibration tool for the BiG X‘s yield metering system. It is based on a weighing system that is installed on one of the trailers in the harvest chain. Both the trailer and the forager are equipped with data loggers that communicate via a mobile network. Calibration takes place in real time as the ‘calibrating machine’ is being filled. The system is highly accurate and is the first system of its kind to eliminate the trip to the weighbridge. |