Get Directions

Get Directions

Get Directions

Get Directions

Krone KRONE Digital

- Machine terminals with intuitive user interfaces optimized to KRONE machines

- Optional AUX joystick and cameras

-

KRONE Digital offers a full range of operator terminals – from entry-level control units to ISOBUScompatible terminals to suit every application. Numerous practical solutions are also available in the field of data management, including the KRONE Smart Telematics machine monitoring system and the universal data management platform, the agrirouter.

- SectionControl for convenient mowing and swathing

- TIM tractor implement management

- KRONE Smart Telematics – a bird’s-eye view of the fleet and fleet data analysis

- agrirouter – data communication across ‘borders’ and down the value chain

- NEXT Machine Management data evaluation

The DS 100 control unit offers individual user interfaces that provide the most convenient control by machine group – rakes, round balers or forage wagons.The special arrangement of the keys makes controlling all machine features especially convenient. The control unit can be integrated into the ISOBUS System for use in combination with an ISOBUS UT. |

Operate any machine function simply by pressing a key. The special arrangement of the keys allows you to use the unit intuitively and without looking so you can focus on the machine itself. |

The DS 100 unit offers an ergonomic design for convenient right-handed use and fatigue free operation during long working days. |

The compact DS 500 terminal has a 5.7" colour display screen and can be operated with 12 function keys, the touchscreen or the scroll wheel on the back. The keys give you a haptic feel, so you can operate them without looking. More comfort comes from the optional AUX joystick that is available for this control unit. |

The moulded handle grip on the back of the unit falls conveniently to hand for comfortable use during long working days. The scroll wheel is also located on the back of the device for optimized use and reduced terminal size. |

You can complement this terminal with a KRONE AUX joystick for easier use and optimized ergonomics. |

|

With an 8" touchscreen, the CCI 800 ISOBUS terminal offers maximum user comfort. The screen displays one function at maximum zoom level and two further functions in a mini viewer, giving you full control of all features. In addition, it combines with AUX joysticks, cameras and SectionControl licence.

|

Even more comfort comes from the AUX joystick that is available as an addition to the CCI 800. Off ering enhanced ergonomics, it provides intuitive use so you can focus on watching the machine. |

Because it shows both the machine’s user interface and the camera feeds, the CCI 800 does not require an extra screen in the cab, saving costs and keeping the cab clutter-free for unhampered visibility all round. |

The CCI 1200 ISOBUS terminal with colour 12.1" touchscreen is the optimum control unit for operating complex combinations. The terminal displays two machines and feeds from one camera on the same screen, providing a complete overview of all relevant information, which saves costs by eliminating the need for additional control units or camera screens. |

The CCI 1200 controls two machines at the same time, so you can operate the BiG Pack and the bale accumulator from the same terminal! The advantage – easier use and cost savings as no extra terminal is necessary. |

As another option, the operator can also view the images from one camera without installing another screen, saving costs and keeping the cab clutter-free for an all round view. |

The CCI 1200 can be mounted for landscape or vertical view to suit individual preferences and cab specifi cations. |

CCI 1200 also supports SectionControl, which eases operator strain. The unit can display the fi eld map and the machine functions at once. |

The CCI 1200 terminal has a rubber shroud as standard, which protects it from shock loads and makes it easier to use. |

Even more comfort comes from the AUX joystick that is available as an addition to the CCI 1200 for enhanced ergonomics and intuitive use. |

The AUX joystick WTK offers optimized ergonomics. Three menu levels are navigated from eight buttons, offering as many as 24 customizable functions. Providing haptic feedback, this control unit allows operators to use it without looking at it. Also, thanks to its ergonomic design, the unit falls easily to hand for fatigue-free use on long working days. |

The keys give haptic feedback, so operators can control the machine without looking at the terminal. This way, they can operate even complex combinations single-handed. |

The terminal screen shows the functions that are assigned to the keys. The red, yellow or green LED on the keypad indicates which level is currently selected, making sure errors are avoided. |

As the KRONE machines have ISOBUS software, they can be operated from the ISOBUS terminal. Likewise, the AUX joystick on a tractor can be combined with the tractor terminal as well as with the KRONE terminal. This makes it possible to customize machine control to the current conditions. |

As KRONE machines are AEF-certified to the ISOBUS standard, they can also be operated from the terminals of other manufacturers. Using the existing tractor terminal to operate your KRONE machine leaves your cab clutter-free and and you enjoy an uninterrupted view on all sides. |

|

Using the multi-functional ISOBUS terminal saves costs as it eliminates the need for a separate control unit for each implement. In addition, it saves time when swapping machines, because the terminal does not have to be transferred. Moreover, operators use just one universal software. All these benefits make your work day easy and smooth. |

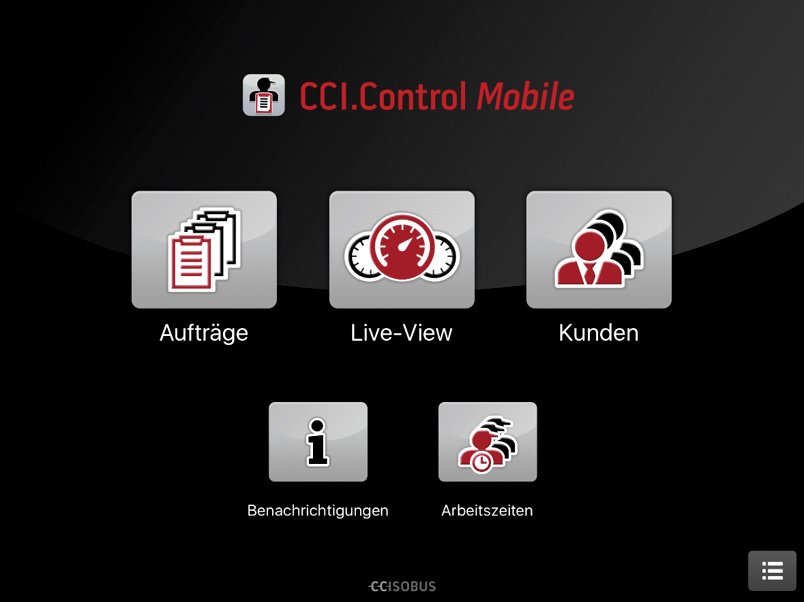

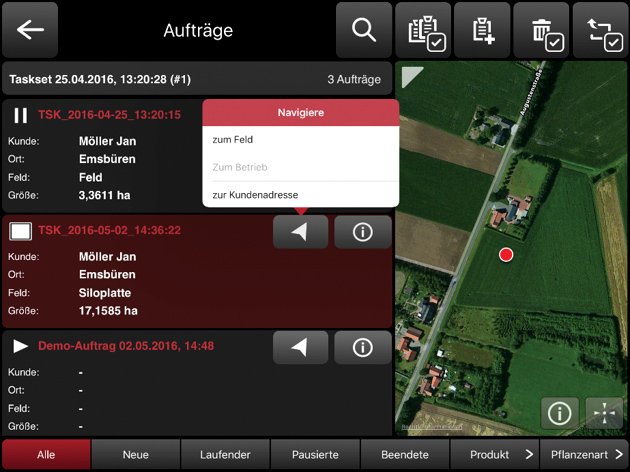

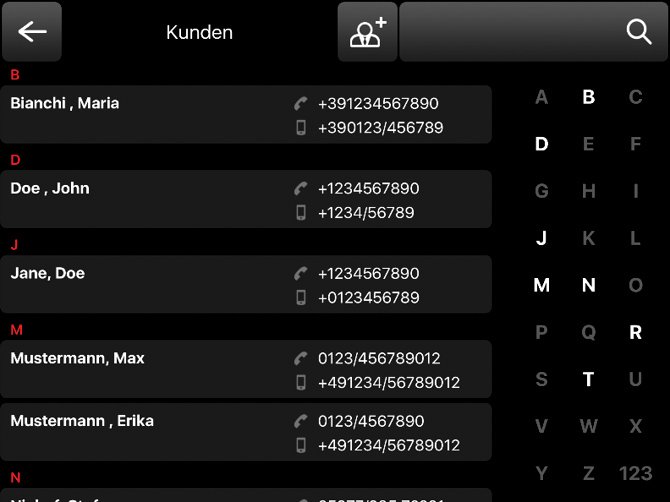

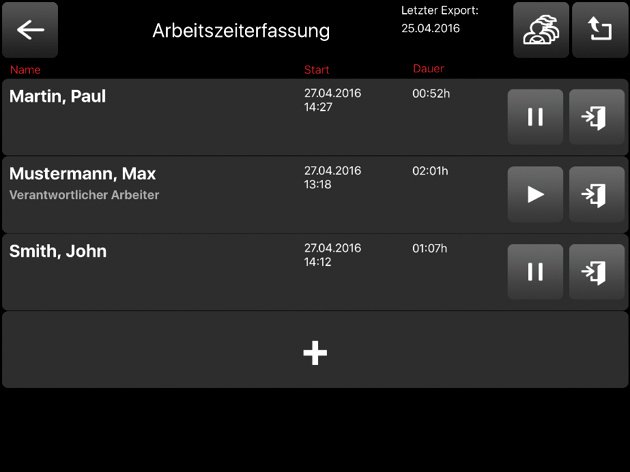

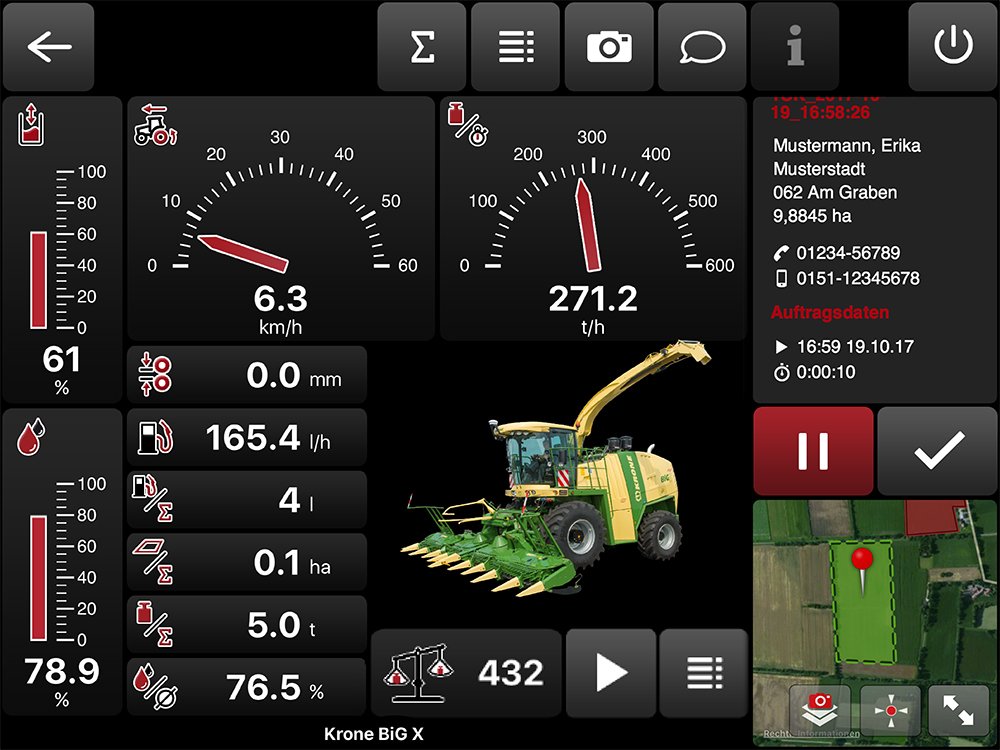

The CCI.Control Mobile App allows you to manage your machine data conveniently from the iPad. Receiving jobs, navigating to the field, monitoring productivity levels and transmitting the finished jobs can be done all from this app, making processes smooth and efficient. |

Its clear, fl at menu architecture makes the app very user friendly, simple and easy to work with. The black background ensures glare-free work at night. |

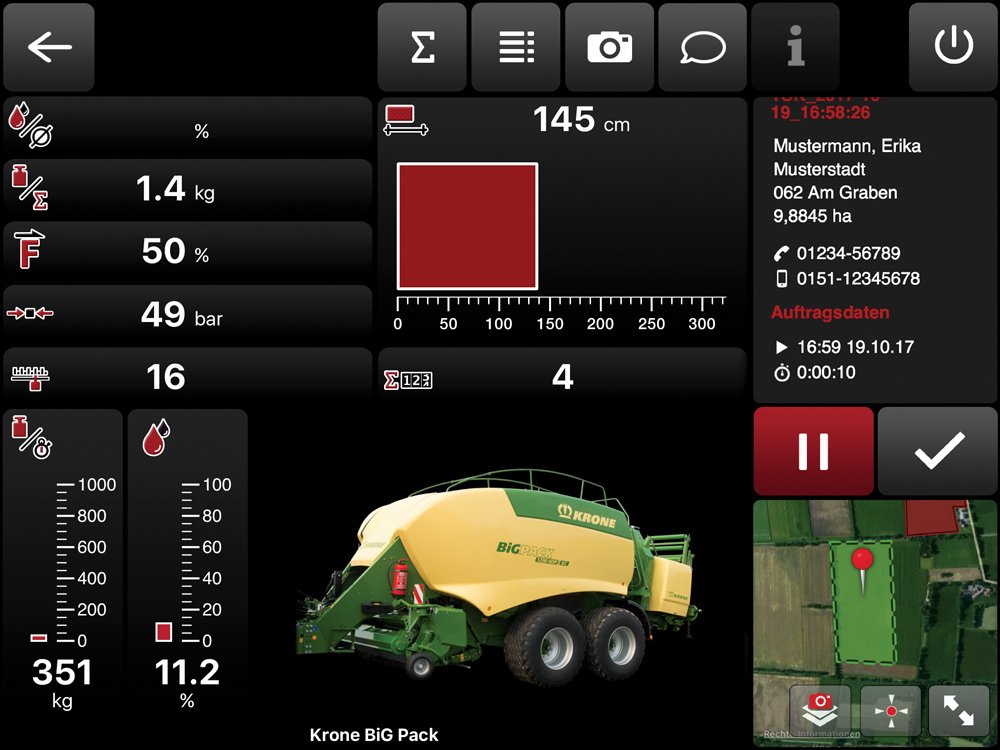

The live view provides all necessary machine data at a glance. Besides, photos and comments are easily included in the job so you can easily recap specifi c aspects of a job even after harvest has long been completed. No data are lost due missing references. |

The navigation software ensures no time is lost in travel. Drivers won’t have to drive to the farm first to get road instructions but go to the field directly. Even if they are unfamiliar with the area, they won’t make detours and are more productive. Managers save time as briefi ngs are no longer necessary. |

Operators can retrieve all customer information from the app. These include contacts, fields and field entrances, which helps avoid farming the wrong field. No time is lost checking back. |

The app also logs the time spent on a job including start and end of work and the breaks This makes billing straightforward and easy. No issues with transposed numbers, poor handwriting or lost time sheets. |

The machine data are wirelessly uploaded to the agrirouter via the KRONE SmartConnect telemetrics box. This is the hardware required to implement data management for KRONE machines. |

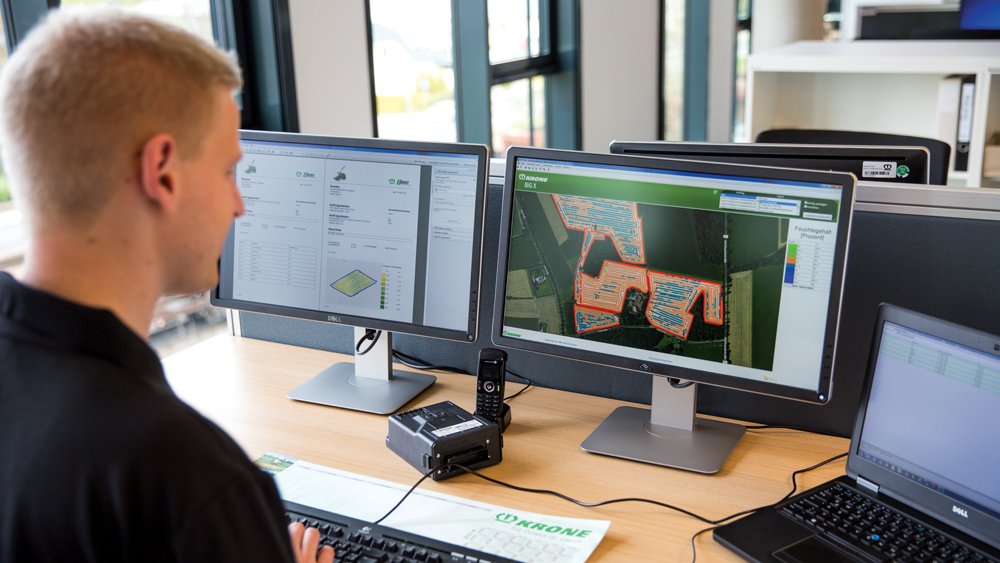

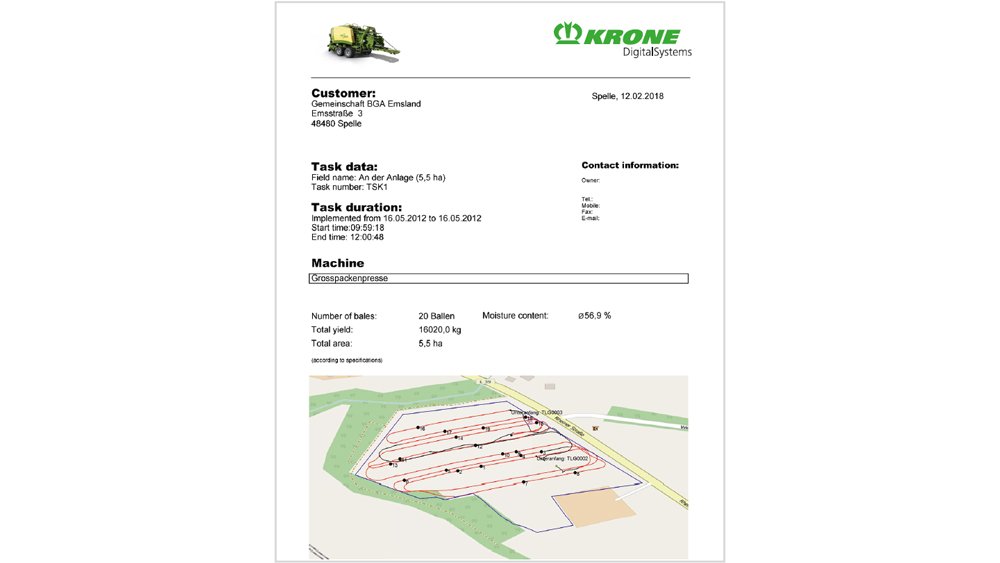

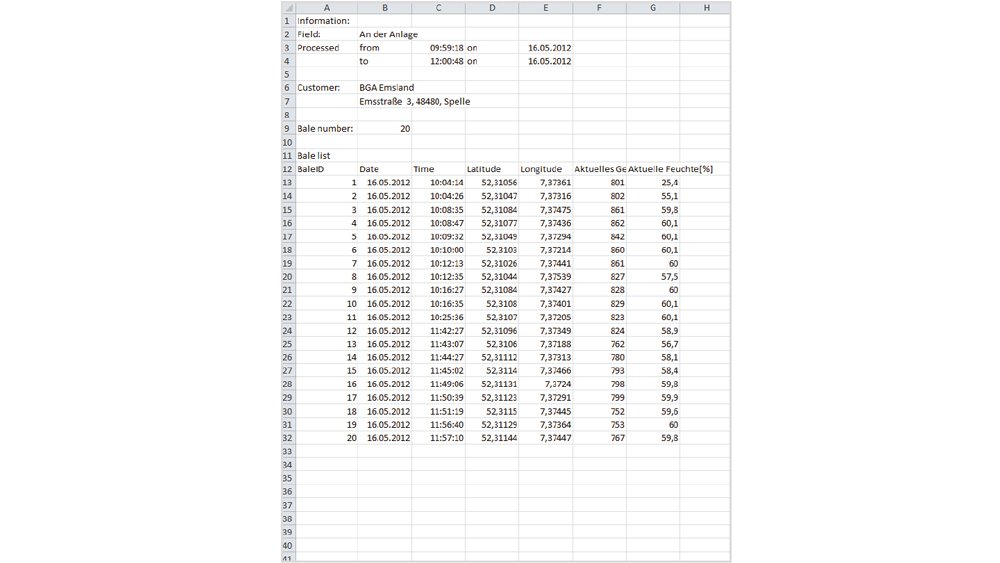

The BiG Data Tools is a software application that evaluates collected machine and job data that are collected in your system. These data can be presented to the farmer in PDF or Excel format as proof of the work done. BiG Data Tools is now available for free download from the KRONE Media website. |

The KRONE BiG Data Tools software visualizes the collected machine data which helps contractors provide evidence of their work to their customers. |

The application also generates reports in PDF using the individual corporate design of the particular farmer or contractor. |

In addition, you can export the data into Excel sheets to evaluate them for specific, individual needs. |

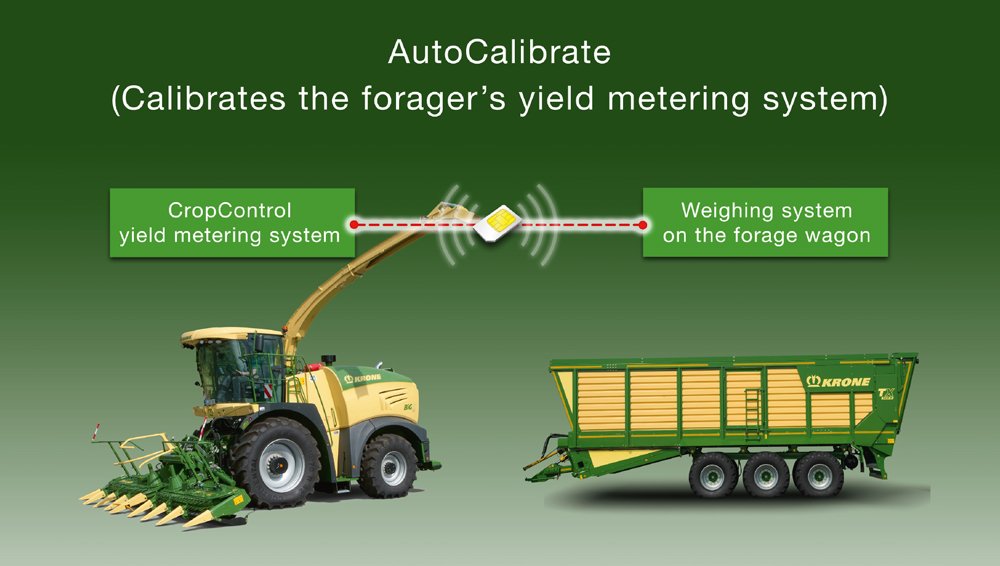

AutoCalibrate calibrates the BiG X yield metering system automatically by using the crop weight information from the KRONE forage wagon. Regular calibration ensures the yields are accurately measured also in varying conditions. When several harvest chains are operating in the same field only one KRONE forage wagon needs to have the weighing system and only one KRONE SmartConnect controller is required. All other trailers in the fleet can be any type of trailers of any brand. |

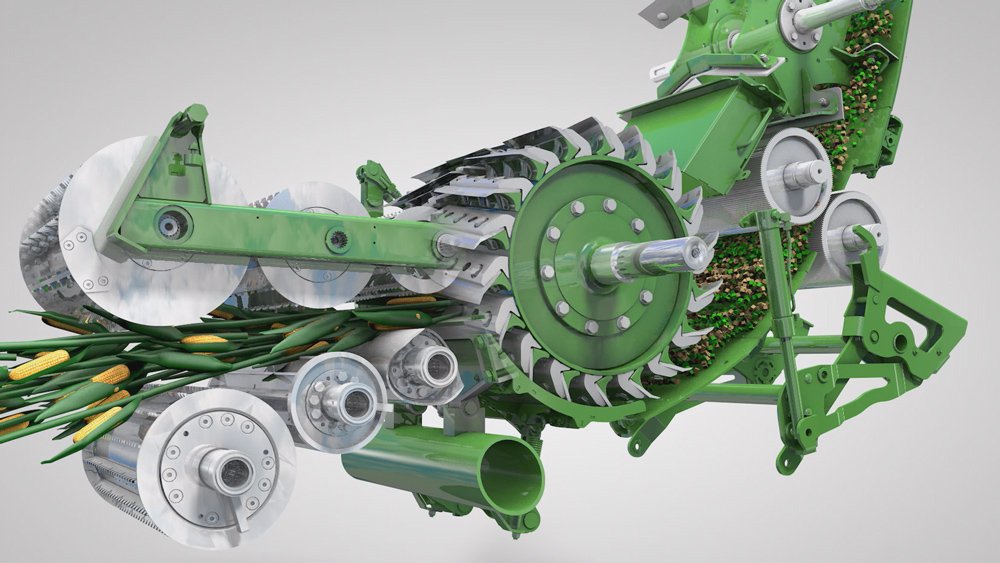

The CropControl yield metering feature on the KRONE BiG X computes the yield by measuring the crop flow. The crop flow is measured by using the speed and the distance between the two leading pre-compression rollers. Regular calibration ensures the yield metering system delivers accurate readings also in varying conditions. |

Only one KRONE forage wagon complete with weighing system and one KRONE SmartConnect controller is required when several harvest chains are working in the same field. All other trailers in the fleet can be any trailer from any make. This gives you maximum flexibility when setting up your harvest chain. |

The forage wagon and the BiG X share data via the SmartConnect controller on each machine. This has integral GPS which ensures the individual load data from the forage wagon data are assigned to the right BiG X. It is possible to mix the fl eets during the day without reprogramming the AutoCalibrate system. |

The system is used from the CCI.Control Mobile App. The BiG X operator simply confirms data reception once. There is no need to key in the weighing results, which eliminates the risk of transposed figures and typing errors. The operator verifies that the correct data are used for calibration, e.g. in situations where the calibrating machine is being filled by two forage harvesters at the same time. |

The KRONE SmartConnect telemetrics unit is the hardware element of the KRONE data management system. The unit has a multiple-network SIM card that connects automatically to the best network for the current location. |

The autologging feature frees operators from any tasks concerning data management, allowing them to concentrate on the job at hand. Autologging means that the machine data are logged automatically for use in the documentation. |

The machine data are wirelessly uploaded from the machine to the iPad using the Wi-Fi signal provided by the KRONE SmartConnect telemetrics box. This is the hardware required to implement data management for KRONE machines. |

A multiple-network SIM card allows SmartConnect to connect to the network currently offering the best signal. If no network is available, the data are temporarily stored to the SmartConnect box for reliable, loss-free data communication. |

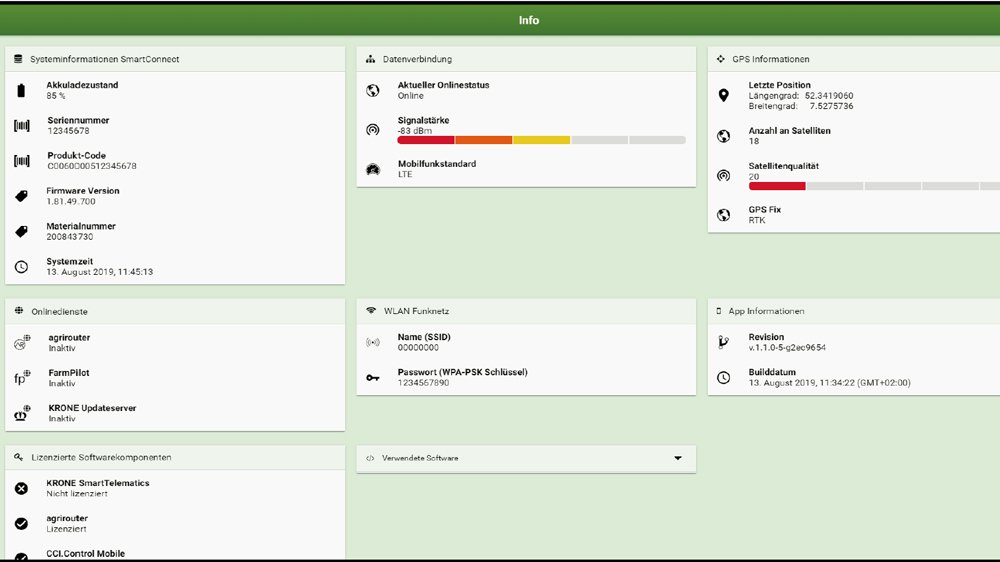

The KRONE SmartConnect telemetrics unit can be set up conveniently from any type of electronic device, such as a PC, smartphone or tablet. The connection is made using the KRONE SmartConnect-Box and Wi-Fi. |