Get Directions

Get Directions

Get Directions

Get Directions

Krone BiG Pack – The new generation

-

Even after more than 25 years of big baler production in Spelle, there is no sign of any let-up in the sheer innovative strength of the KRONE engineering team, as is evident from the new series of BiG Pack balers. Over several years of intensive development, they have come up with a completely new generation of BiG Pack balers which incorporate many well-known technologies and, above all, offer a significant increase in comfort. Almost all of the existing features have been upgraded and adapted to user requirements

- Lights: In addition to the modern full LED light specification, KRONE also offers various LED work light packages to suit individual needs.

- Bale chamber: All models gain the much longer baling chamber from the 1290 HDP for firmer, tighter and heavier bales.

- Cleaning the machine: A brand new hydraulic knotter fan is available as an option which cleans the knotter permanently. The best part of this is that the air flow is also directed to the areas behind the twine boxes cleaning further areas of the machine.

- The cutting system: The VariCut system offers buyers the flexibility to choose between two blade cassettes with up to 26 or 51 blades each.

- Electronics: The new BPW tandem axles and a choice of tyre options ensure stable rides behind the tractor.

- Active pick-up: The camless Active pick-up from KRONE is now available as a hydraulic option.

- Flywheel: The well-proven and convenient driveline without shear pins.

- Twine boxes: A new and most functional approach – learn more about the new twine boxes.

- Twines: Original KRONE twine gives peace of mind.

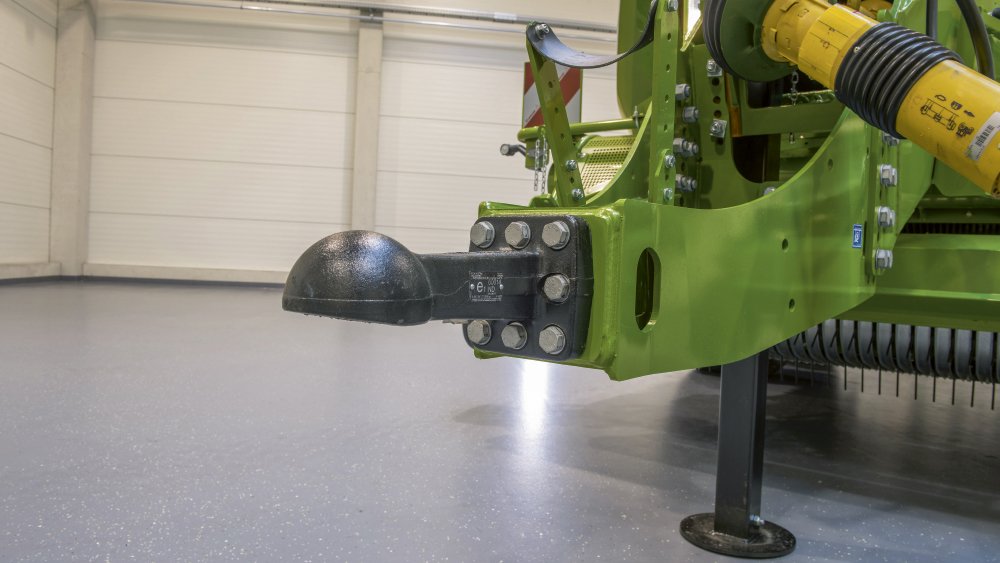

- Drawbar: Choice of hitch options to suit all requirements across the globe.

- VFS packers: Tried and tested just got better! Read more on the updated VFS variable filling system.

- Axle: The new BPW tandem axles and a choice of tyre options ensure stable rides behind the tractor.

- Options: Further options to boost increase operator comfort.

|

The BiG Pack 1270 offers a 120 x 70 cm chamber – a very popular size especially among farmers. Its patented MultiBale system forms one big bale from up to nine individual packs. The big packs are easier to collect in the field and the smaller packs are easy to handle and distribute in the barn. Also, the new BiG Pack 1270 produces much higher-density bales than its predecessor, a boon for maximising transport and storage efficiencies. |

The KRONE BiG Pack 1290 (VC) has the 120 x 90 cm chamber which is the most popular chamber size on the international market – not only because it makes very economic use of the twine but also because these bales stack very well. The new version has a much longer chamber and this has a positive effect on the shape of the bales. In addition, the model is now also available with the 51-blade VariCut cutting system. |

Churning out more than 100 straw bales per hour at bale weights of up to 500 kg, this is the benchmark machine in terms of performance and density. Looking for efficient long-distance haulage of straw and hay bales? Then HDP technology from KRONE is for you. |

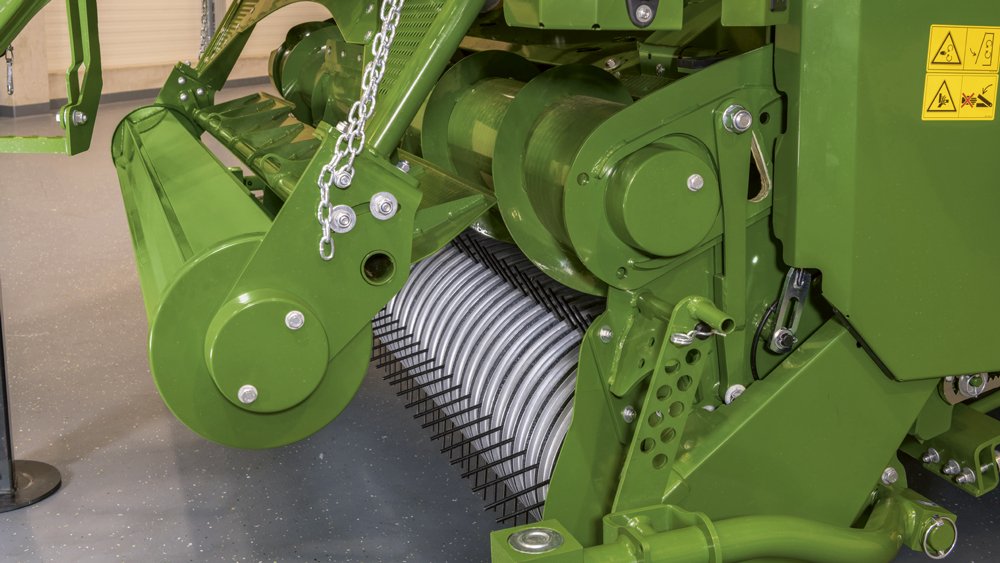

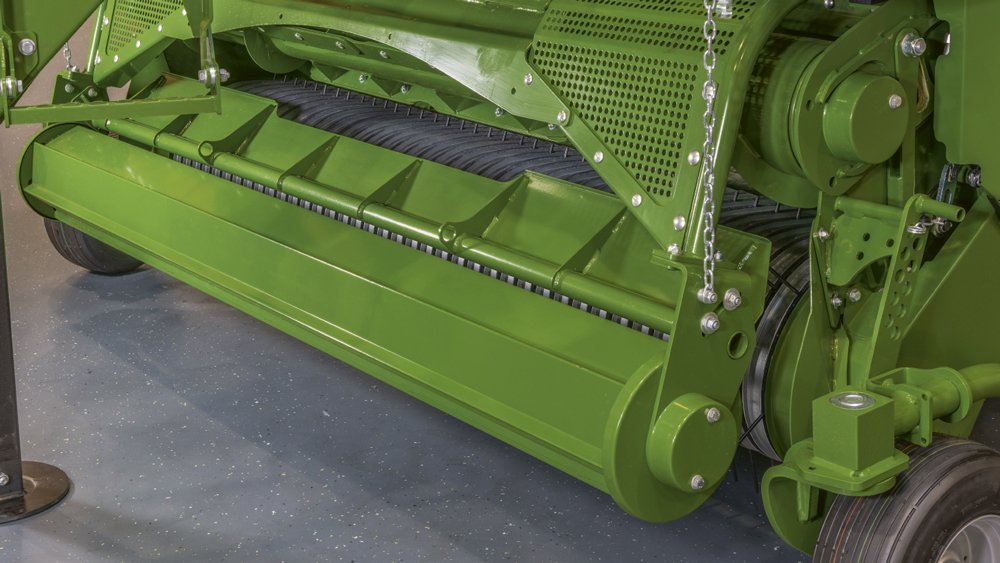

KRONE Active Pick-up – a clever combination of the tried-and-trusted camless EasyFlow Pick-up plus an additional powered feed roller. The two combined make a perfect match that delivers a pick-up performance second to none on the market while keeping wear to a minimum. More than that, they feed the material in an exceptionally smooth flow into the machine – regardless of whether it is equipped with cutting system or not. Increase your work rates and throughputs. |

Working at a width of 2.35 m (DIN 11220) and kitted out with five rows of tines spaced 55 mm apart, the camless EasyFlow Pick-up does a clean job every time. The combination of the powered feed roller and the side-mounted augers tick all the boxes in dry, brittle material, delivering massively increased throughputs. |

The standard depth limiter adjusts the pick-up to work in long stubble, reducing the strain on the gauge wheels which only lift the pick-up on very uneven terrain. |

|

|

The pneumatic caster wheels follow every curve and are height-adjustable without tools. The sward is even protected on curves, thanks to their excellent castering behaviour. |

A side-mounted poly V-belt drives the pick-up and the rotor. Its slip is constantly monitored so the belt. When there is an overload, the powerflow to the pick-up and the cutting system is automatically cut off. To resume operation, the blades are retracted/extended either automatically or manually. |

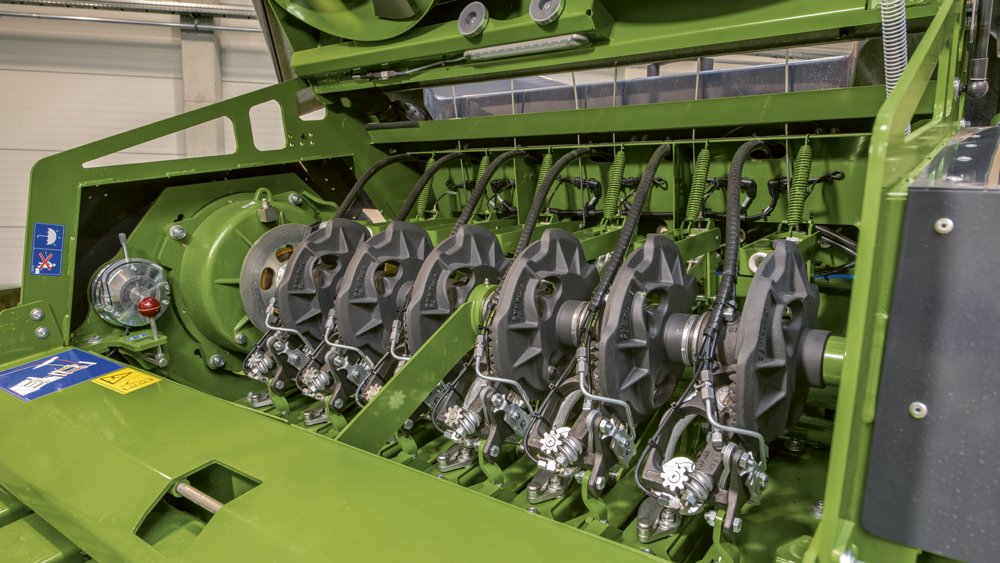

The VariCut 51 system allows operators to select the blades in sets of 51, 26, 25, 12, 5 and the VariCut 26 offers sets of 26, 14, 12, 6, 6 blades. The preselected group is engaged hydraulically from the cab. All cams are attached to the shaft and can be combined to form individual groups. |

A service aperture above the blades can be opened in a single action for removing deposits. The area around the blades and the individual blade protection system on the VariCut 51 is kept clean with an integrated compressed air blower. |

For easy removal and maintenance, the single-piece blade cassette pulls out conveniently to the side on an optional transport frame that fits on a pallet truck. It can be removed from the machine when baling hay or other crops that are not chopped. |

|

PreChop is an integral front-mounted chopping unit on the KRONE big balers of the new BiG Pack 1270 (VC), 1290 (VC) and 1290 HDP (VC) series. It has 96 rotating blades and two rows of 47 counterblades that cut the material to a nominal length of 21 mm. More than than, PreChop also defibrates the stalks visibly. |

Chopped and nearly dust-free straw makes perfect bedding in poultry houses and cow cubicles as well as in pig and beef cattle housing. More than that, it is used as animal feed that adds fibre to low-fibre rations but also as mulch in strawberry plantations and nutrient medium in mushroom production. The treated straw has better absorption qualities, spreads more easily in the livestock house, and prevents the slurry drains from blocking up while supporting manure mineralization. |

The large cutting rotor is 525 mm in diameter and features 96 pivoting blades in a helical arrangement. Rotating at 3,000 rpm, it feeds the material through two rows of counterblades with 47 rigid blades each and from here on to the BiG Pack pick-up. A turbulence generator strip between the counterblades ensures a top quality chop. The intensity of the two counterblades can be adjusted in one of five positions without tools. All blades are reversible for a long service life. |

When used with PreChop, the feed roller on the Active Pick-up can be stopped and switched off if necessary. The crop press roller can also be moved away. The PreChop has a high lift-out height, enabling the baler to be used without removing the PreChop. |

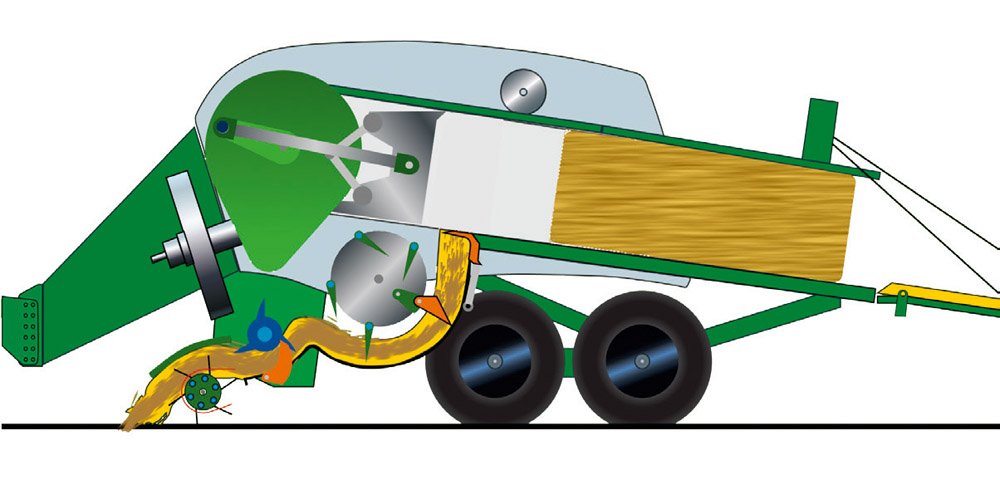

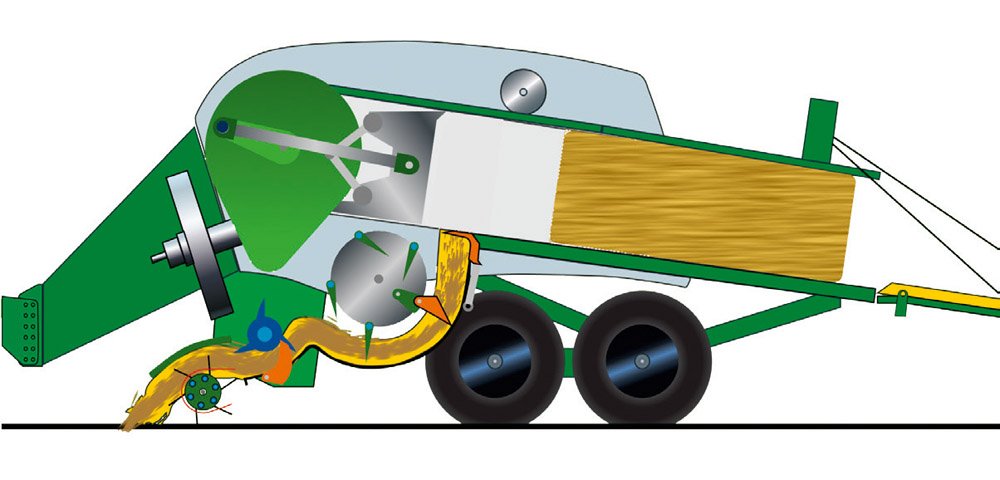

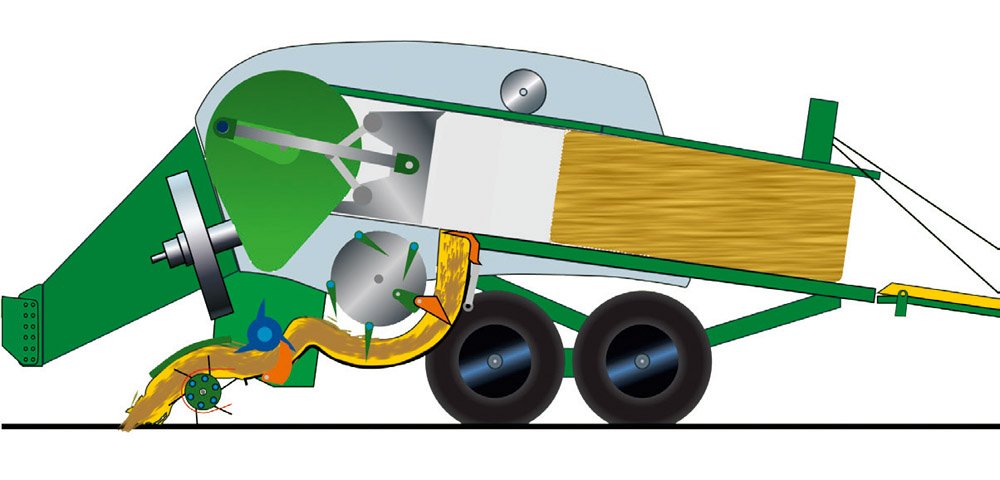

Tried and tested gets even better! In line with this adage, the VFS variable filling system has received a performance boosting update. Optimum mixing and effective pre-compression in short and different crops were not enough for the KRONE engineers. They have now implemented a feature that allows operators to control the level of pre-compression from the terminal and which keeps them informed on the current load. |

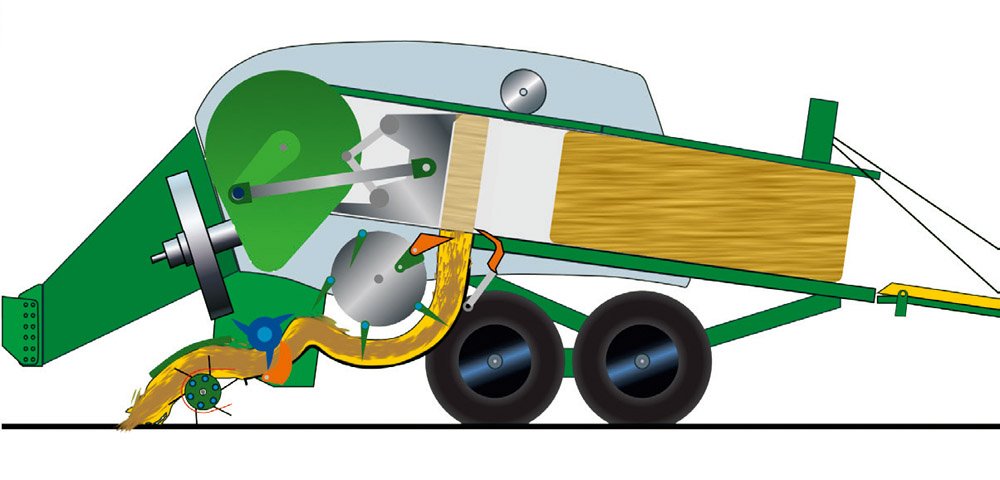

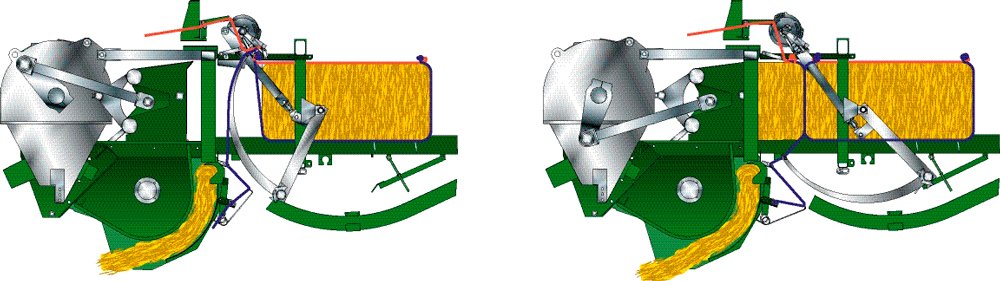

The VF system uses four packer rakes, one feeder rake and one sensor swing. The packers move in a shared cam track, the feeder rake in a separate cam track which swings into and out of path. |

As long as the feeder cam track does not swing off path, the packers and the feeder continue feeding material into the feed chamber, pre-compressing it as they go. The sensor swing with its retaining tine traps the material inside the feed chamber, preventing it from entering the baling chamber. |

When the pre-chamber is filled to capacity, the sheer volume of the material pushes the swing and retainer into the baling chamber. This clears the way into chamber and triggers the feeders. |

The entire cam track of the feeder rake moves off path so the rake feeds the pre-compressed material into the baling chamber. After that, the sensor swing and cam track return to their previous positions. |

The new BiG Pack has a completely new VFS control system which also has a new sensor that monitors the swing. If there is not enough straw in the pre-compression chamber to produce a full-size pack, an electric brake triggers an extra stroke that collects more material. If the brake is not triggered, the system keeps feeding material into the baling chamber at each turn of the packer. The best part is that operators can control the level of pre-compression, wad thickness and wad number electrically from the cab. From the terminal screen, they can watch the pre-chamber being filled at each turn of the packer and interfere by altering the torque that triggers the mechanism. The brake is not triggered as long as the system is in 1:1 feed mode. |

The inner cam track of the packers is split in two parts for easy replacement when worn or damaged. The bottom part of the cam track is 20 mm wider and boasts a much more heavy-duty design. Also, the idler wheels and actuator arms are all sourced from BiG Pack HDP II to beef up the new BiG Pack generation. |

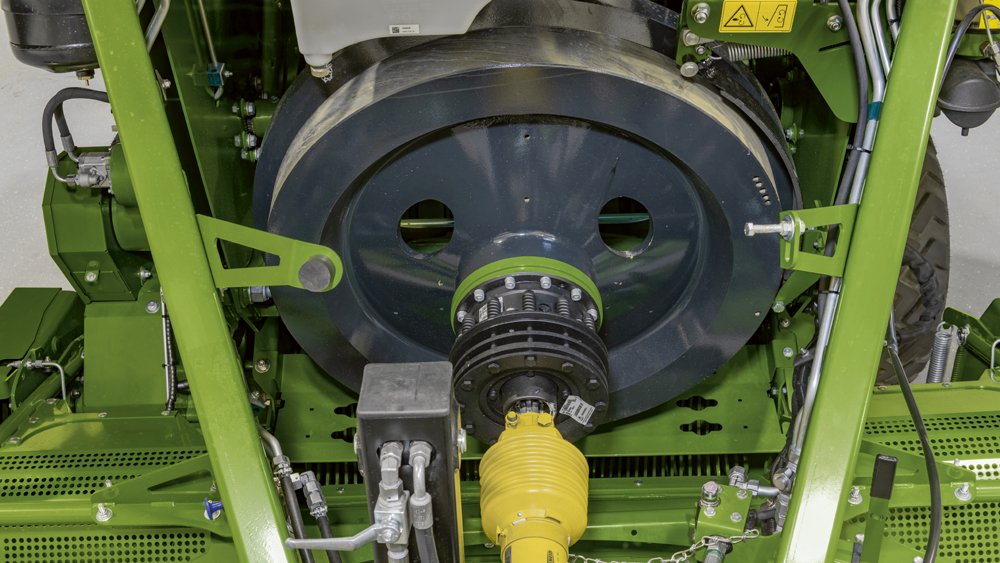

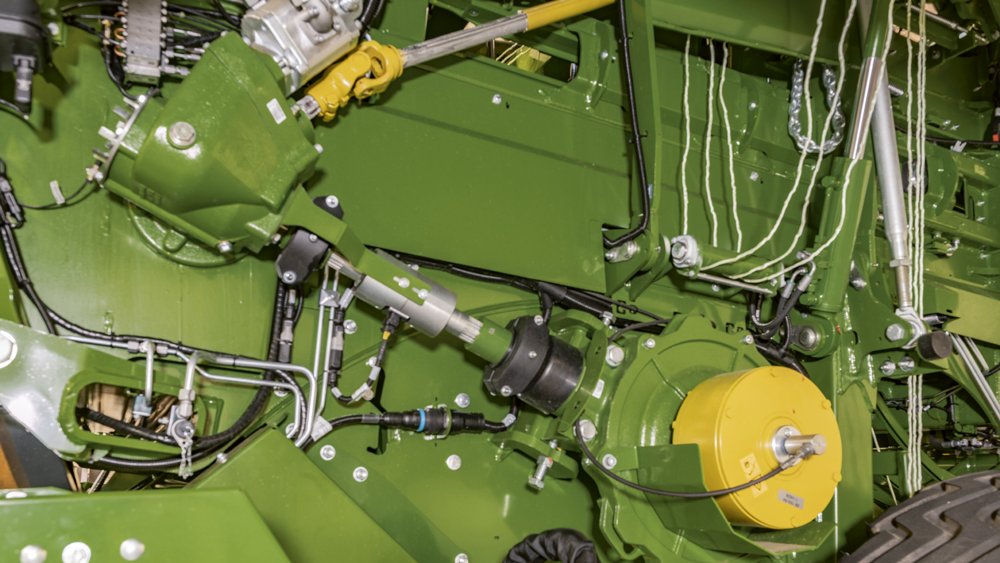

KRONE has always preferred massive flywheels that are able to absorb peak loads and improve the fuel efficiency of such a big baler. All chains have been replaced by gearboxes and driveshafts for optimum efficiency throughout the entire powertrain. You won’t find shear pins on the KRONE BiG Pack drivelines but overload clutches protecting all drives. |

Large flywheels prevent bounce and guarantee a quiet running system. The flywheels absorb peak loads and the machine maintains a consistent work rate whilst requiring significantly less tractor power – for more peace of mind, better fuel efficiency and minimum wear. |

On start-up, the driveshaft to the BiG Pack is protected by a slip clutch. When there is an overload an automatic cutout clutch is activated protecting the baler effectively from the energy that is stored in the flywheel. The two clutches are located in front of the flywheel for easy access and servicing. |

On KRONE big balers, power is transmitted to the packer and the knotters via robust, low-maintenance drive shafts, gears and overload clutches. Buying this technology means buying into dependability and comfort. |

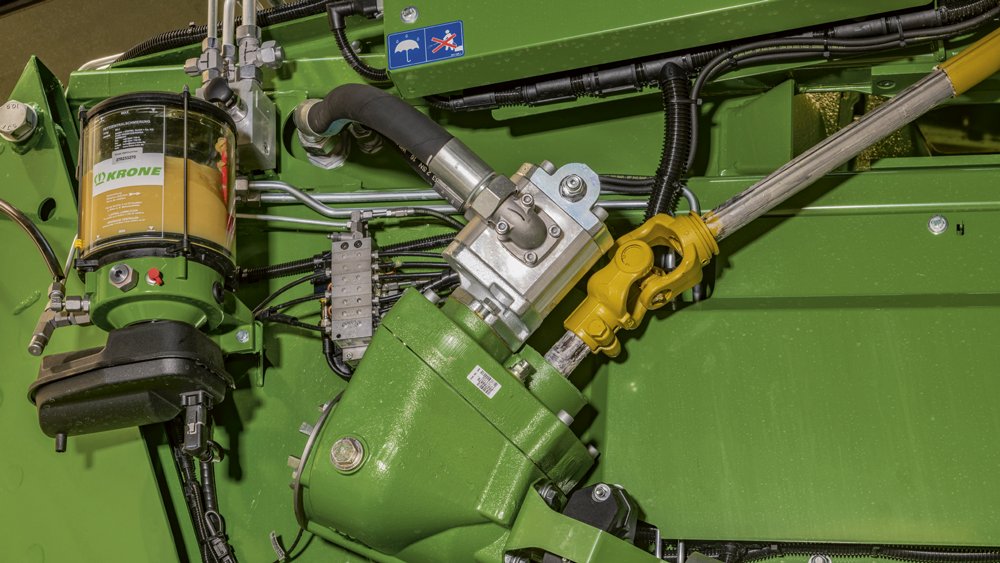

The VariCut belt drive, the bale chamber control system and the KRONE PowerClean system have their own hydraulic on-board system so these assemblies do not tap into the tractor’s oil reserve. |

BiG Pack features a 20% longer baling chamber that has now a full-width top plate to produce even firmer, tighter bales especially in very dry crops and at high work rates and throughputs. The on-board hydraulic system with automatic baling pressure control ensures firm bale shapes and tidy edges, even in wet conditions and in different crops. |

The length of the baling chamber has been increased by 20% to 3.60 m. The BiG Pack 1290 HDP chamber has standard wear plates at the front end which help press the material into perfect bales and reduce machine wear. Up to six massive rams operate the top and the side walls of the chamber. The heavy-duty yoke is designed to cope with exceptionally high loads in non-stop operation. |

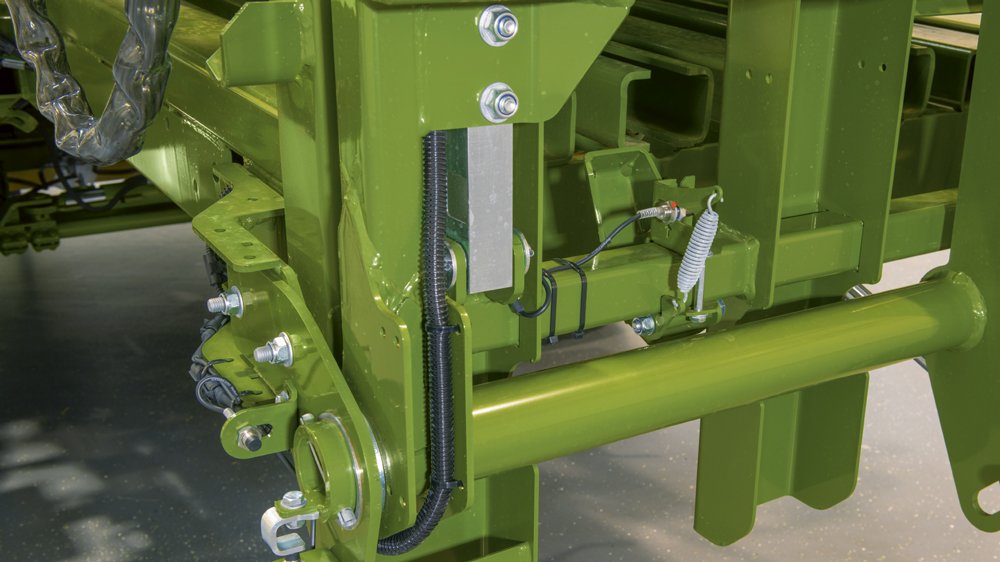

The BiG Pack features a very strong frame that also has a hitch to pull a bale for example. The BiG Pack features a very strong frame that also has a hitch to pull a bale accumulator for example. |

|

KRONE equips all BiG Packs with a star wheel that measures the bale length electronically. Arranged in the middle of the baling chamber, the wheel is encased for protection from objects and debris. |

The operator selects a density between 0% and 100% on the control box and the baling force control adapts the baling pressure automatically. This way, you get uniform and consistent bale densities also in varying conditions. |

The pusher dogs are deselectable so you can choose whether only some are in action to push out the last bale or all of them to clear the the chamber. When the operator enables the pusher dogs, the baling pressure is automatically reduced to a customisable level. This makes ejecting the bale easier depending on the crop. In auto mode, the pusher dogs carry out several cycles. |

There is no way around double knotters when the task is to make high-density bales. The technology feeds the upper- and under-thread to the knotter without tensioning them. The threads are fixed inside the knotter only for the short moment of tying the knot. This reduces significantly the strain on the thread and on the knotter increasing the reliability of the system. |

The knotter feeds an upper and a lower twine to the bale as it is being pressed and ties the twine with two knots – one at the front end of the bale (starter knot no. 1) and one at the rear end (finishing knot no. 2). The lower twine is threaded through the needle by a tensioning system that surrounds the base and the two ends of the bale. The upper twine is supplied to the bale directly by a tensioning system and encloses the top of the bale. This system allows the machine to apply maximum baling force in any type of crop. |

|

The updates on the twine boxes refer to functions and features but also to the styling. The twine box is integrated in the side panel and opens without tools. The panel keeps the twine balls clean and free of debris. 15 balls feed the twine in a logical arrangement. The box even holds 15 kg balls as an alternative to the customary 11 kg balls – a small detail that expands your operating range significantly. |

In addition to the main twine boxes, KRONE is the only manufacturer to offer two extra twine boxes that are mounted at the rear end of the machine. In between them, the boxes hold six 15 kg twine balls, allowing operators to extend their range by approx. 250-300 bales. |

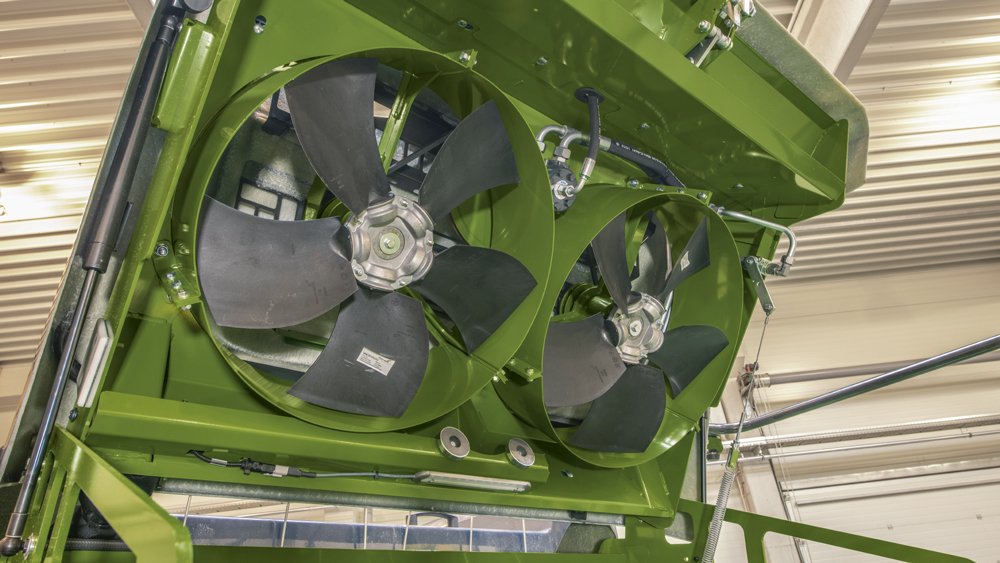

The KRONE PowerClean is a pioneer development that cleans not only the knotter bay but also large areas of the machine. Maintaining a high air pressure inside the knotter bay, the system prevents material from collecting here in the first place. From here, the air flow is directed to the areas behind the twine boxes and down to the axles, cleaning the machine at maximum convenience and ensuring maximum safety in the field and on roads. |

The large knotter bay opens easily without tools for convenient access to the knotters. The turbines stop automatically when the deck opens. |

Two turbines feed the air from the rear into the knotter bay, creating an overpressure and preventing debris from depositing here in the first place. From here, the exhaust air is directed to the area behind the twine boxes and down to the axles, keeping these areas clean too. |

The knotter bay is covered by a stylish plastic deck which gives maximum protection. |

The KRONE MultiBale system converts your BiG Pack 1270 into a veritable multi-purpose machine. Available as an option, the kit allows you to make huge bales and clear even large fields fast and efficiently and at the same time deliver your customers small packs that are easy to handle in the barn without a loader. KRONE MultiBale is a unique system that gives you an edge over your competitors and helps expand your business. |

Up to nine single bales are packed in one big bale: The award-winning MultiBale system changes straw handling processes in the barn and stable. The small packs are 0.30 m to 1.35 m in size, allowing users to handle them easily and without the need for costly machinery. This said, you can of course continue baling regular 2.70 m long bales. |

On the move, the operator sets the required number of bales on the control box in the cab, selecting the total length of the big bale and the number of small packs. The small bales are held together with two strings, whereas the big bale has four. Naturally you can also produce conventional full-size single bales tied with six strings. |

In MultiBale mode, two knotters knot the small packs and the others tie the big bale, assisted by a divided needle yoke. The two needle yokes are coupled and uncoupled by a controlled latch. For the double knotter to tie the knot, it needs to be supplied with twine. Therefore, the other strings simply pass through underneath the knotters. The small bales are tied with two lengths of twine (1). When the bale is complete, the two yokes are automatically re-engaged so that all the knotters are now supplied with twine (2). Then the big bale is tied. |

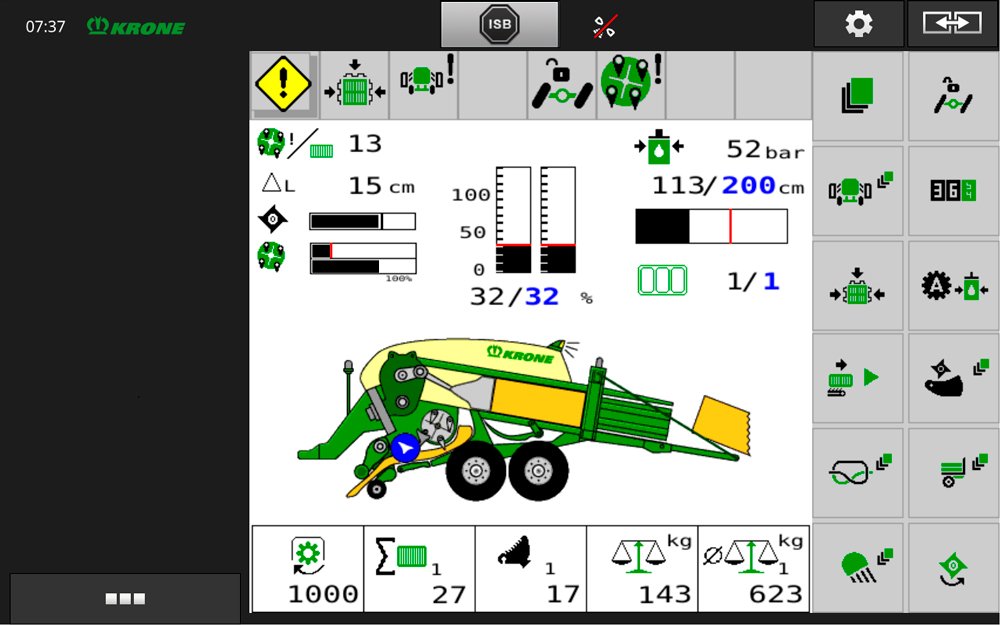

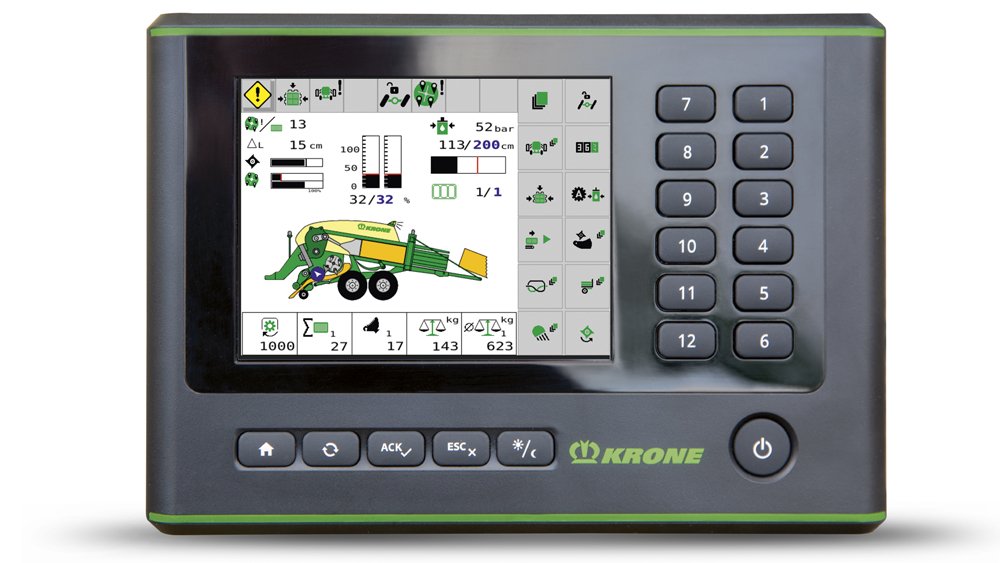

Even the entry-level DS 500 from KRONE offers convenient and comprehensive control of all major functions from a colour touchscreen. The CCI 800 and CCI 1200 ISOBUS terminals take user comfort to the max, offering one screen that displays both the machine user interface and the images that are fed from camera. |

The compact DS 500 terminal has a 5.7" colour display screen with a clear layout for easy use. You can either operate the machine from the 12 function keys or the touchscreen and the dial control on the back of the device. |

The CCI 800 ISOBUS terminal with 8" touchscreen serves as user interface and also as camera screen which feeds the images from the bale accumulator for example, offering multi-functionality that saves costs and frees cab space for uninterrupted view. The individual machine functions are shown in mini-view format on the bright, high-resolution colour screen. |

The new ISOBUS-compatible CCI 1200 terminal with its 12" touch screen displays the views of two universal terminals (UT) on one screen. This allows the operator to control combinations such as a BiG Pack and a BaleCollect from one single terminal and view footage from several cameras on the same screen – a money-saving feature that provides a better all-round view from the cab. The individual machine functions are shown in mini-view format on the bright, high-resolution colour screen. |

All ISOBUS-compatible KRONE machines can also be controlled from the tractor’s existing ISOBUS terminal. Simply connect one single cable and enjoy your customized user interface on the terminal in the cab. Optional controls like the WTK joystick make the tractor even easier to operate, depending on the tractor specification. |

The cutting system, the twine boxes, the bale chute and the pusher dogs as well as the LED work and service lights are operated from these BUS controls on the machine. The buttons are backlit and the LED comes on to confirm the specific function has been correctly enabled. |

Regular servicing increases reliability and lifespan of your BiG Pack. Therefore KRONE developed an innovative folding mechanism that opens the side panels hydraulically for convenient service, repair and twine refills. LED lights come on automatically when you open the panels and lower the twine boxes for excellent visibility day and night. |

In order to service a machine properly it is necessary to access all service and maintenance points easily and conveniently. Following this logic, the BiG Pack side panels can also be controlled from the cab or from the keypad panel at the rear end of the machine. Opening wide and clear, they give plenty of headroom and access to all service points at eye level. |

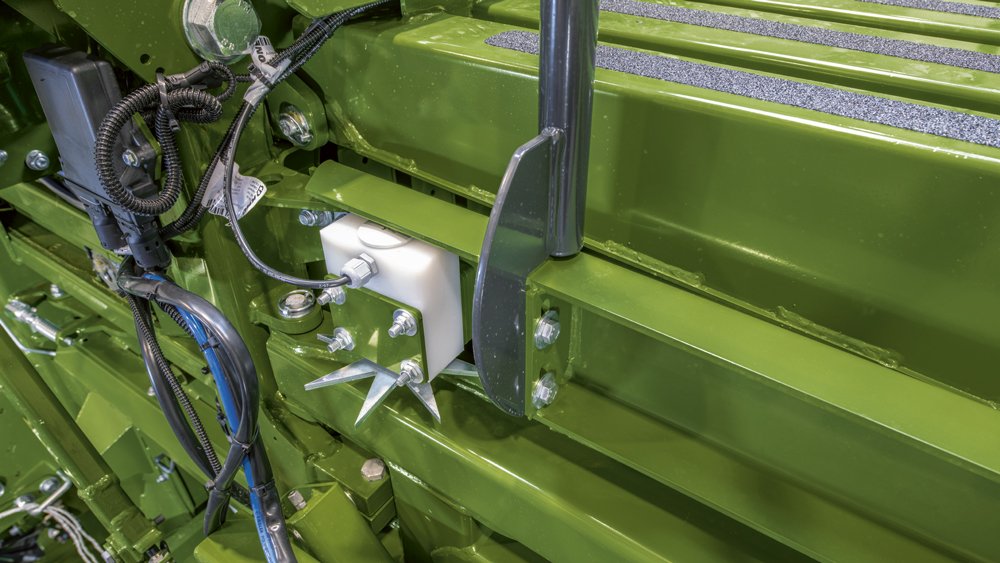

The auto lubricator and its large grease reservoir allow operators to spend less time servicing and maintaining the machine. The unit sits underneath the left panel where it is protected from UV radiation. |

An extra water tank with an integral soap dispenser sits at the rear of the machine, allowing you to wash your hands after a brief intervention on the machine and get back on the tractor with clean hands. |

| Name | Link |

| Brochure PDF | Download |

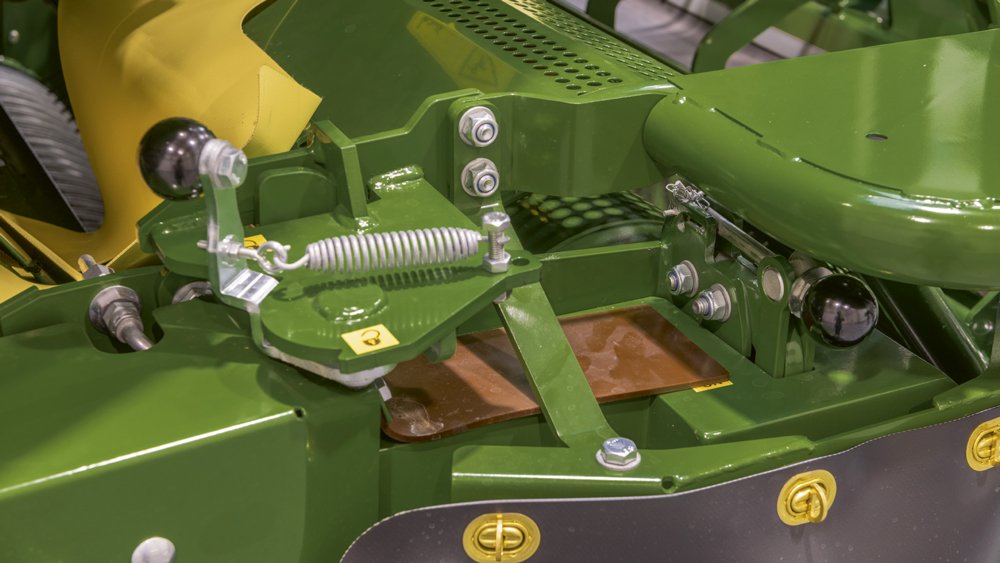

The massive crop press roller ensures a continuous flow of crop into the machine. Its height is conveniently controlled from a crank and suspension comes from springs.

The massive crop press roller ensures a continuous flow of crop into the machine. Its height is conveniently controlled from a crank and suspension comes from springs.