Get Directions

Get Directions

Get Directions

Get Directions

Krone BiG X 480 | 530 | 580 | 630

|

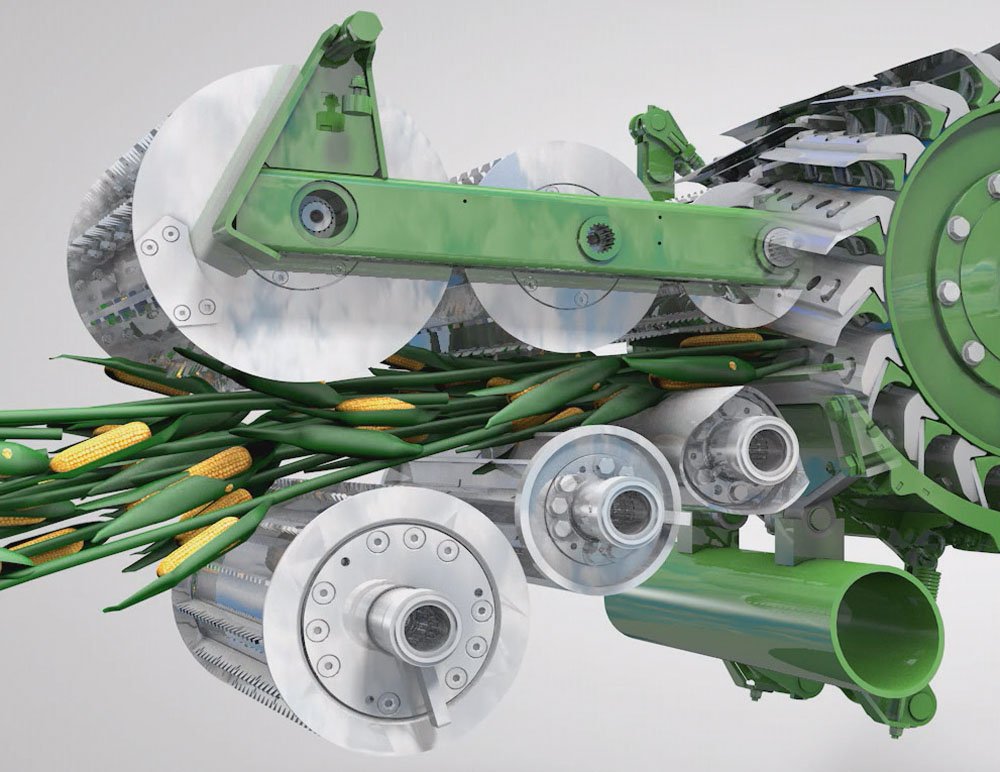

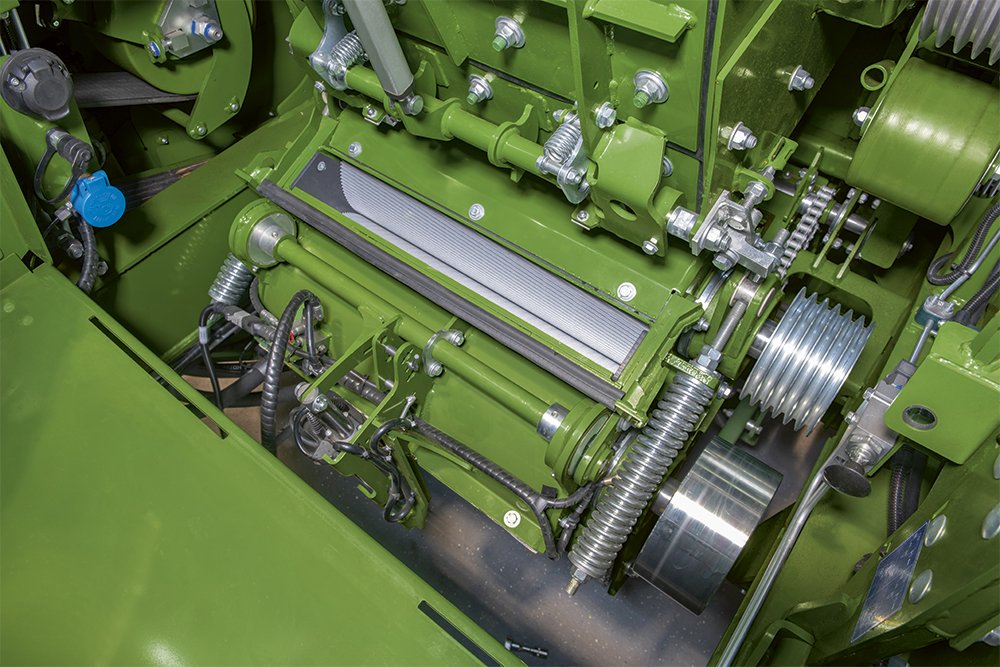

On a BiG X, it is also the intake system that has an influence on the quality of chop. The six intake rollers compress the chopping crops consistently at a high pressure so that it is easier and more precisely to chop. The hydraulic drive of the intake system allows operators to choose between setting the cutting length manually or automatically. |

Six pre-compression roller and 820 mm distance between the front roller with metal detector and the rearmost roller provide for improved pre-pressing and added protection from metal foreign object during fast intake. The hydraulic driveshaft automatically adjusts the LOC in line with the maturity of the crop, which is detected by the KRONE AutoScan sensor. If the engine speed falls below 1,200 rpm with increasing load, the intake and header are stopped automatically while the chopping drum is running. This prevents crop blockages due to excessively slow rotational speeds, and thus saves time and money. |

|

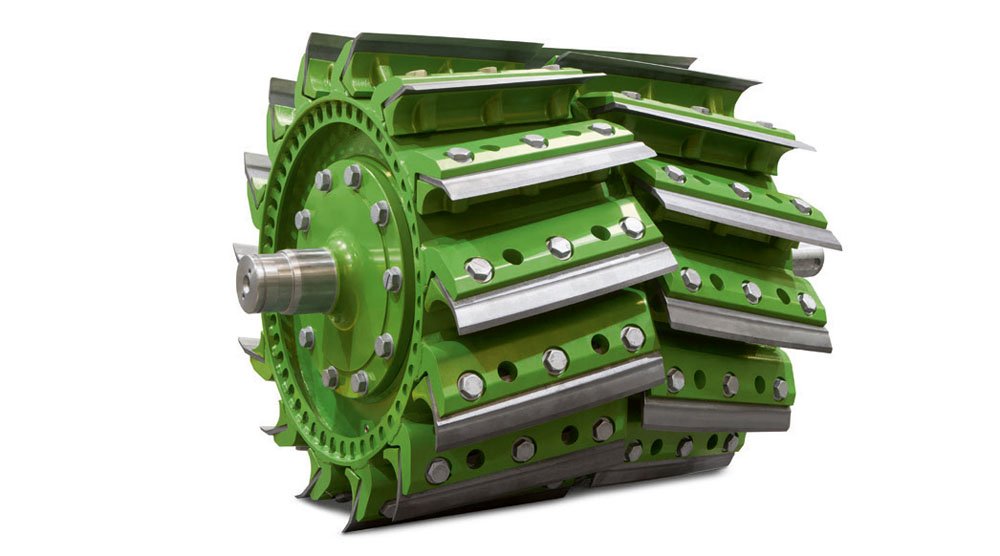

The MaxFlow chopping drums are specially designed for conditioning of high-quality silage. Harvesting wilted crops with unevenly formed swaths is a challenge for the chopping drum; therefore, its blade supports have a special shape which leaves more room under the blades. Larger ‘pockets’ and the spring-loaded drum floor result in extremely smooth running and high power reserves. So BiG X makes light work of temporary crop accumulations. |

OptiMaize XL - 20 blades: This drum cuts the kind of long lengths that are called for in some countries. Cutting length range: 20 blades: 5 - 29 mm |

OptiMaize L, M - 28 blades: The 28-blade chopping drum is fit for universal application; with half a set of blades, it is perfectly suited for use with larger cutting lengths. LOC range: 28 blades: 4 - 22 mm; 14 blades: 8 - 42 mm |

OptiMaize M, S - 36 blades: With a high flowthrough volume in a wide range of cutting lengths, the 36-blade chopping drum pays for itself very quickly. With half a set of blades, it is perfectly suited for use with larger cutting lengths. LOC range: 36 blades: 3 - 17 mm; 18 blades: 6 - 34 mm |

Room for conveying: The blade carriers are arranged and designed to allow plenty of space under the blades. More room for conveying crops means higher flowthrough volume and quieter running, particularly with large cutting lengths. |

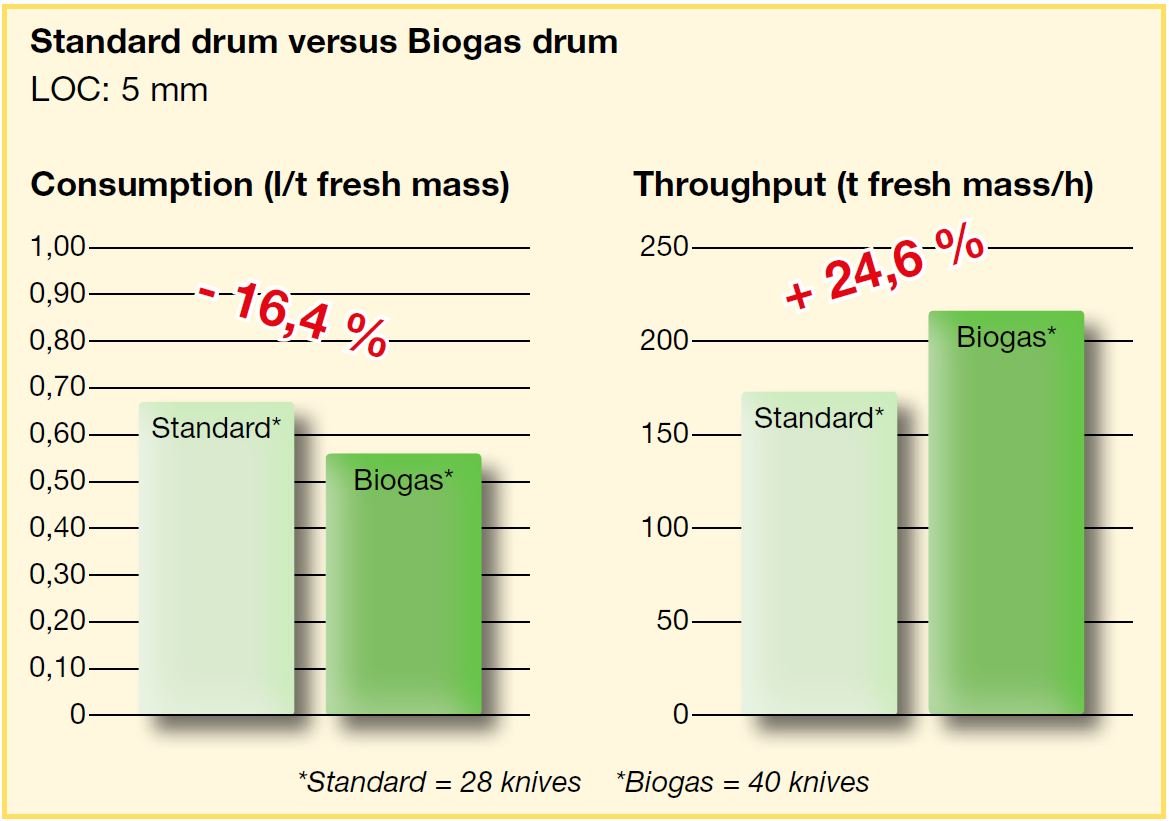

With short chop lengths, the 40-blade KRONE biogas drum increases the throughput by almost 25% compared to the 28-blade MaxFlow chopping drum. The fuel consumption per ton of chopped crops is reduced by up to approx. 16%.* |

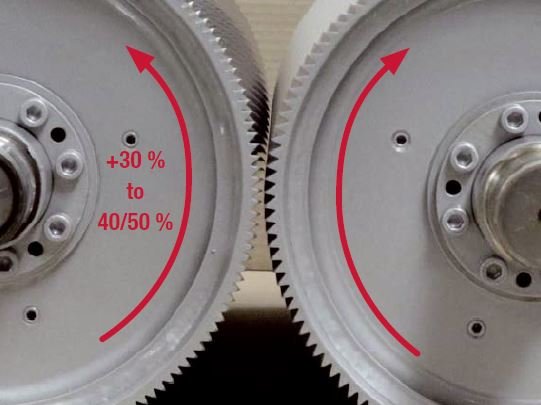

The two toothed rollers operate at a 30% speed difference. This standard difference can now increase to 40-50% to deliver 100% conditioning and fracturing of long chops as produced by OptiMaize XL. |

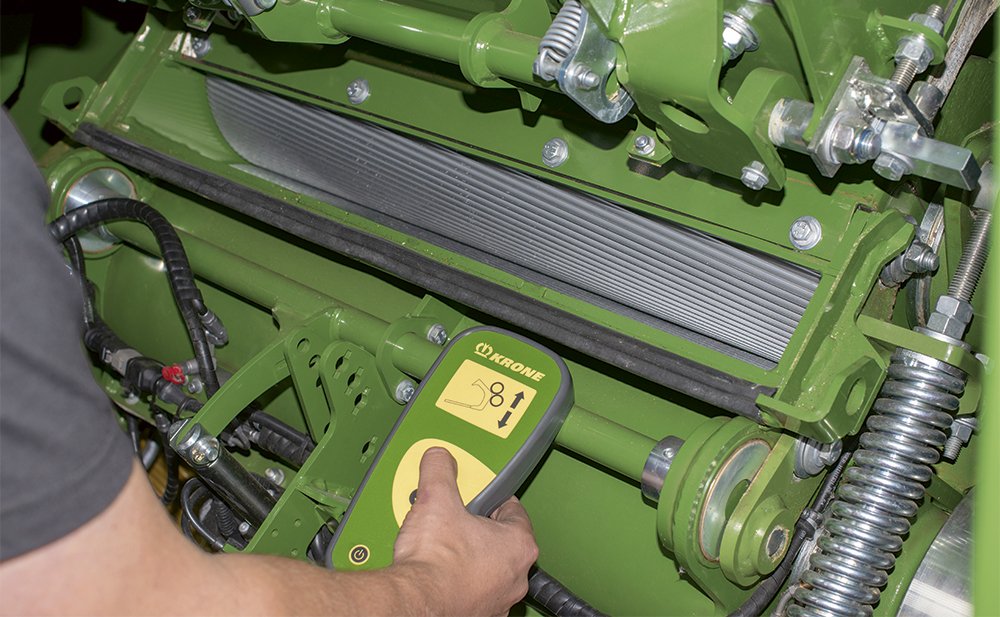

The operator can control the roller distance from the cabin, adjusting it infinitely to the current conditions. The current setting is shown on the display screen. |

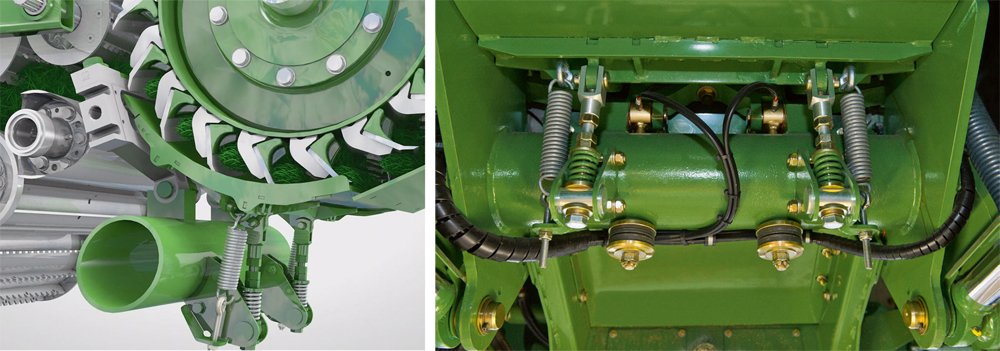

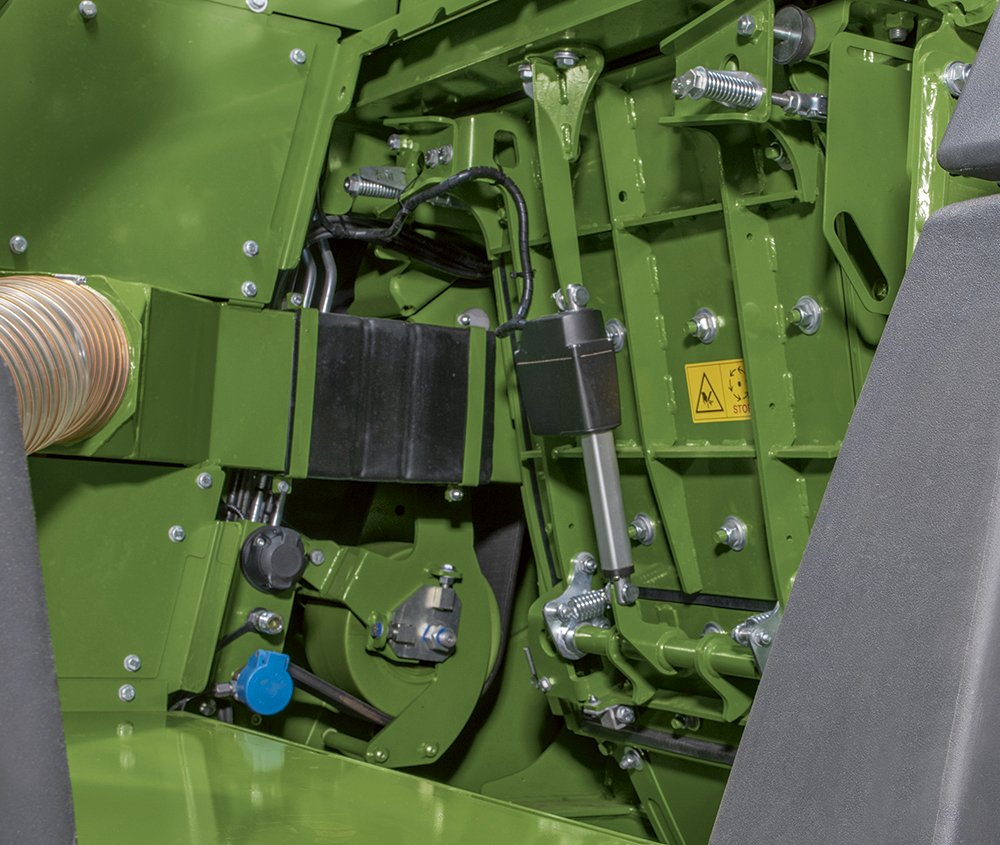

VariQuick is the system that allows operators to converse BiG X very quickly from maize to grass and the other way round. A chain drive (electric option) moves the corn conditioner out of or into the crop flow. If the corn conditioner is not used for longer periods of time, you can lower it and remove it from the machine by pulling it out to the side. |

Quick changeover: Change from maize to grass or from whole crop silage to grass on the move – either using a chain drive with crank handle or an electric motor as an option. This allows BiG X to change from maize to grass or from whole crop silage to grass flexibility and quickly. |

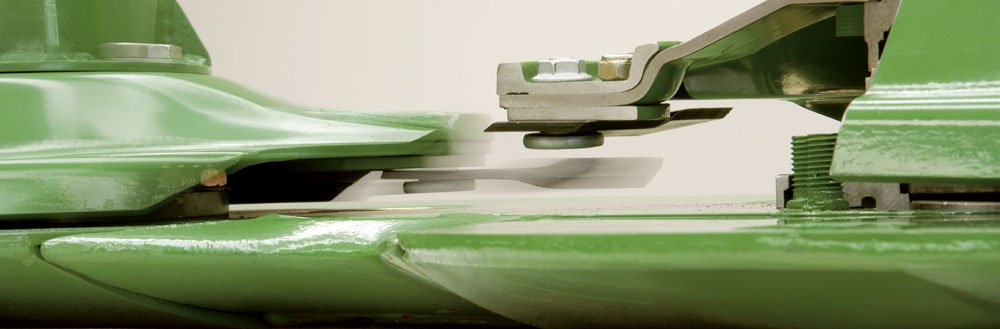

VariStream comprises spring-loaded floors beneath the chopping drum and behind the discharge accelerator rotor. The system ensures blockage-free and smooth operation, even in varying volumes of crop. The technology allows operators to utilise the forager to its limit and use less fuel per hour. |

The spring-loaded chopping drum floor is connected to the anvil of the counterblade at the front. As these are readjusted, the gap between the blades and floor does not change. So any movement of the spring-loaded drum base in compensation of bigger crop lumps will not affect the quality of chop. |

The spring-loaded rear wall of discharge accelerator ensures maximum discharge capacity and fills the transport wagon dead on target in all conditions. |

The crop throw is controlled from the cab by adjusting the door in the backplate on the crop accelerator.This way, operators can adjust the throw quickly to the current filling situation. As the accelerator needs less power to cover a short distance, the operator can free up engine output and use it for chopping and higher throughputs. |

For a small discharge distance and trailers driving in parallel, it is of advantage when the crop stream is ejected at slow speed. The "weaker" stream frees up power reserves that can be used for an increased chopping performance. |

With the trailer following behind, the crop stream needs to be ejected from the spout at a higher speed. A strong, tight stream is needed to cover the long distance over the tractor to the rear wall of the trailer. |

The discharge scoop are designed for a high discharge capacity and guide the crop flow towards the middle. |

The crop discharge is controlled via the hinged flap on the rear wall of discharge accelerator. For a short-distance discharge, the flap moves out of the crop flow, so there is little contact between the crop and the accelerator. For a long-distance discharge, the flap moves into the crop flow, so there is more contact between the crop and the accelerator. |

The throw is quickly changed on the joystick controls. |

The additional discharge distance control in the armrest offers maximum operator comfort. |

The hinged flap on the rear wall of discharge accelerator is adjusted infinitely via an electric motor. |

The multi-coupler system of the BiG X allows operators to couple headers fast, easy and dependably from the seat, reducing changeover times when preparing for road travel or different crops.This way, more time is spent on productive work. |

The camless EasyFlow 300 S and 380 S pick-ups by KRONE have neither deflection rolls nor cam tracks. Compared with conventional pick-ups, EasyFlow has up to 58% fewer moving parts, which makes it impressively smooth running, low-wear and therefore inexpensive in service and maintenance. EasyFlow operates 30% faster for cleaner gathering and increased productivity. |

At a working width of 3.00 m or 3.80 m and six rows of tines arranged in W-shape, the camless KRONE pick-ups EasyFlow 300 S and 380 S are extremely efficient and leave no crops in the field. Depending on the swath width and your working speed, you can vary EasyFlow rpm steplessly from the driver's seat or have it adjusted automatically to the current forward speed without the operator having to interfere. Its curved round steel bracket gives the header the flexibility to pivot through a large angle and makes for easy attachment and removal. |

As a specialist for whole crop silage, KRONE XDisc is highly versatile. XDisc stands for loss-free harvest and convinces with a clean cut. The huge 900 mm diameter auger makes the unit enormously powerful and has no trouble picking up very long and bulky material. |

If the system is suddenly overloaded, the impact is not directed to the spur wheels in the cutterbar, instead the roll pins in the sprocket drive shaft shear off. The pinion shaft continues spinning, jacking up the mowing disc in question and moving it out of the risk zone and the orbit of the neighbouring discs. As a result, SafeCut prevents damage to the spur wheels and the neighbouring discs. The roll pins are replaced within a few minutes, saving costs and minimizing downtime. |

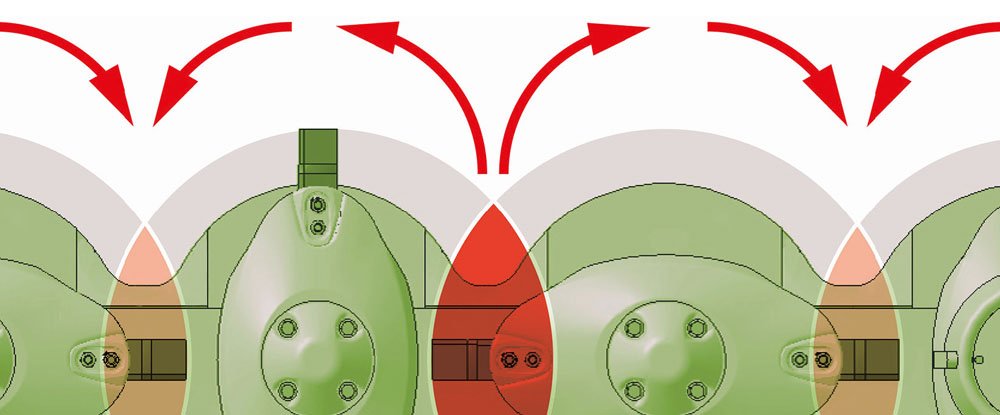

For stripe-free cuts: With some mowing discs turning in pairs towards each other and others turning away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest swaths. For a stripeless swath, we have therefore increased blade overlaps on the cutter blades turning outwards between the discs turning away from each other. In addition, the blades turning to the rear are set further apart to encourage a smooth flow of large volumes of crop. |

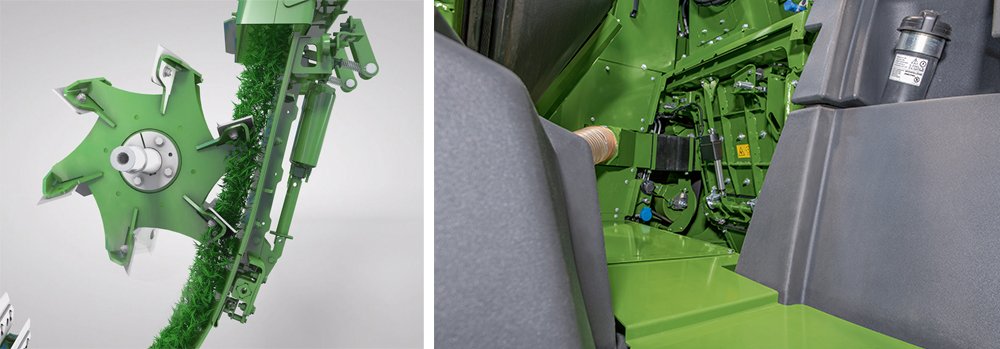

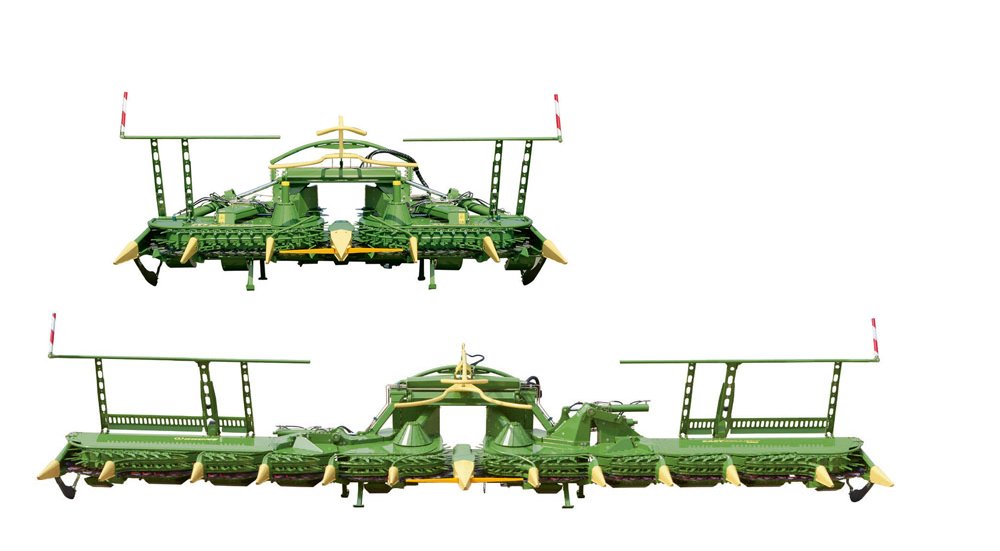

The variable-row EasyCollect header is a versatile unit that feeds the stalks lengthwise into the machine, which translates into an unsurpassed quality of chop, as a coarse chop is the last thing livestock farmers or biogas producers want. The unique collector principle cuts labour costs and has proved its worth time and again the world over. |

Unique – High-power & high-efficiency: With working widths between 4.50 m and 9.00 m, the BiG X 480, 530, 580 and 630 can be fitted with two- or three-piece variable-row headers for maize chopping. The endless collectors convey the cut plants to the middle, where they are fed lengthwise to the intake. This guaranteed top chop quality with few excess lengths. |

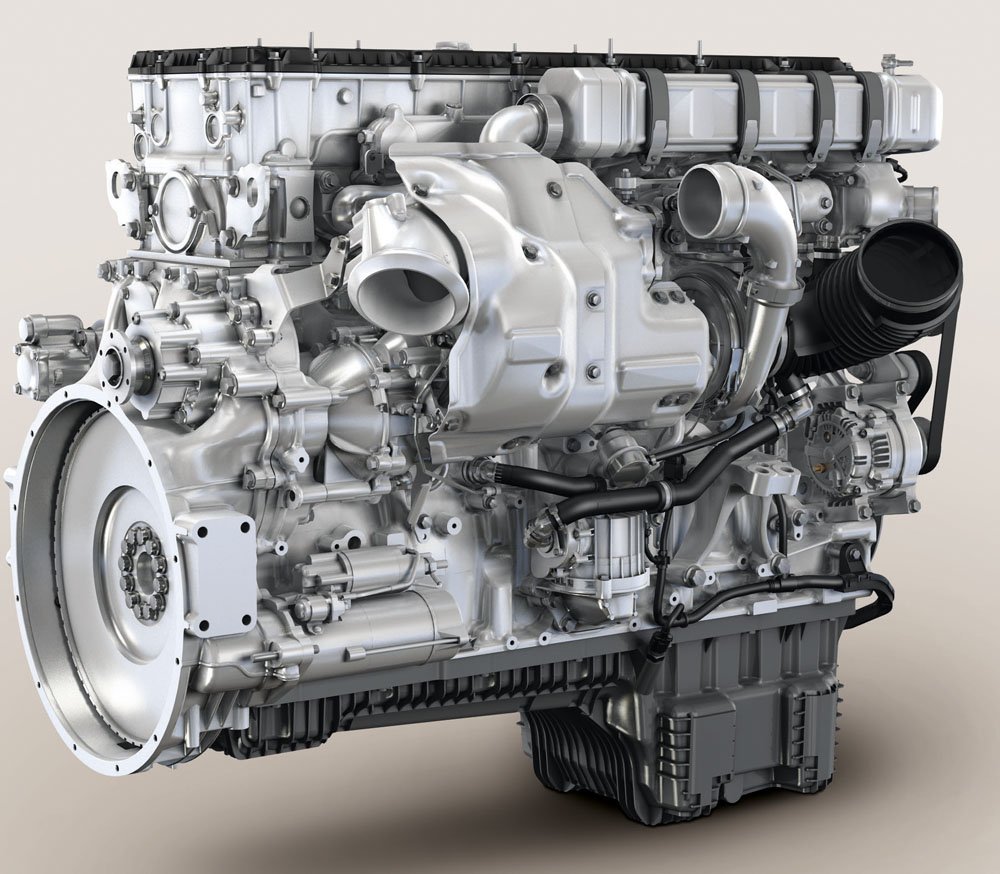

Cutting-edge technology from MTU takes engine power and economy to a new dimension. Common Rail injection and optimal torque synchronization translate into smooth running, low fuel consumption, high efficiency and minimal maintenance. The innovative KRONE power management guarantees highest efficiency with maximum throughput. |

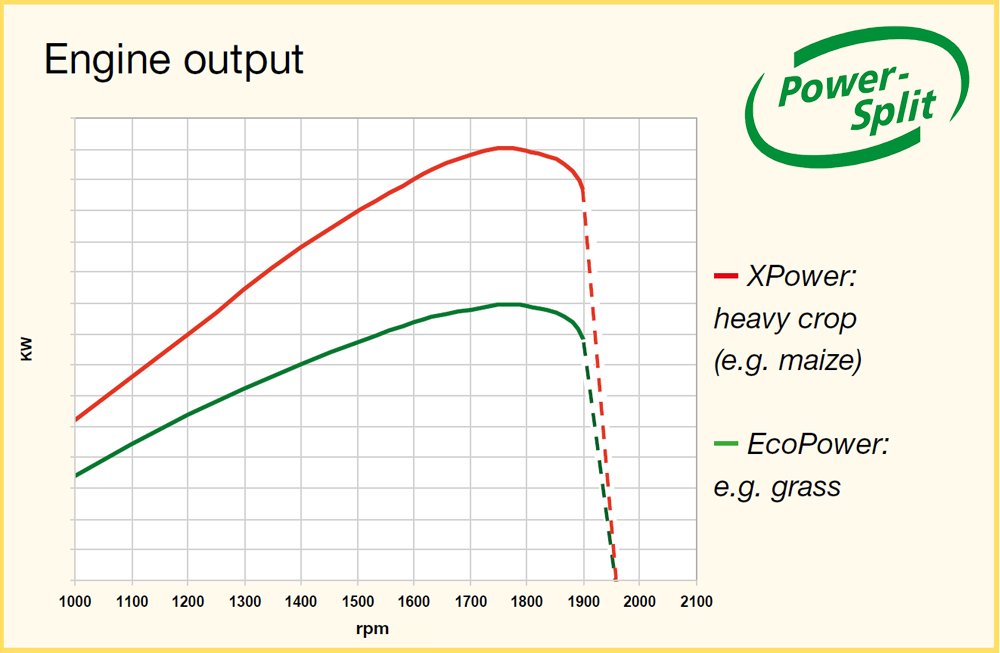

BiG X 580 and 630: PowerSplit: As an option, operators can control the engine output with a touch of a button. They can operate the machine in the fuel-efficient Eco-Power mode whenever the full power is not needed. Vice versa, when the full power is needed, you simply switch to X-Power mode. The machine does this automatically and continuously variably depending on the current conditions. Another useful feature is the optional engine speed management which boosts efficiencies and fuel economy. |

Transverse in-line engines: The engine is mounted sideways and far back for optimum weight distribution. The power flows from the engine directly to the components for crop flow - a setup that ensures maximum efficiency. The Common Rail injection makes the MTU in-line engines very efficient. |

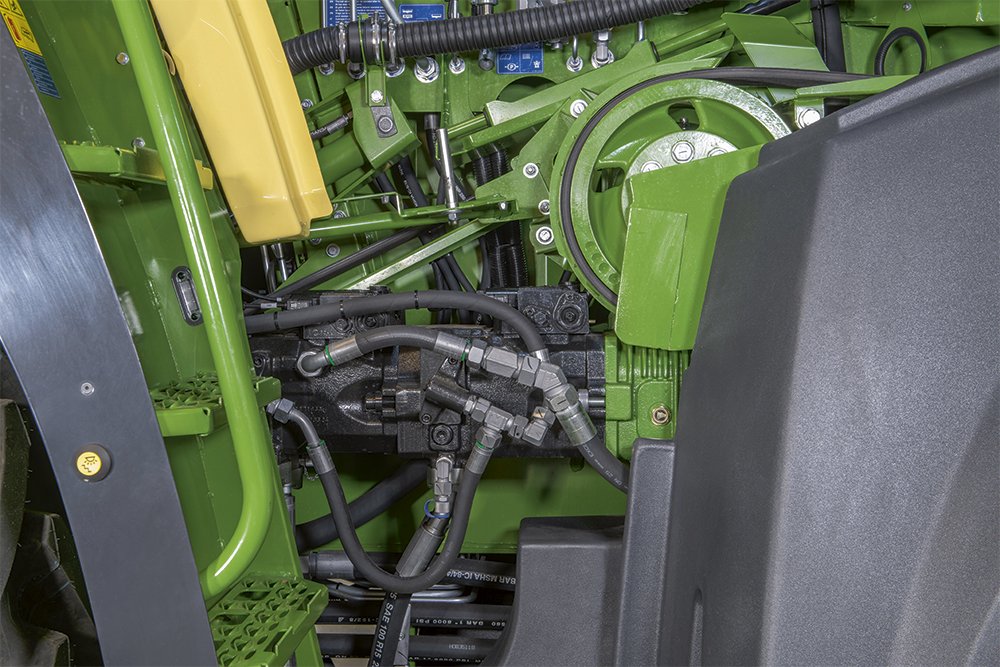

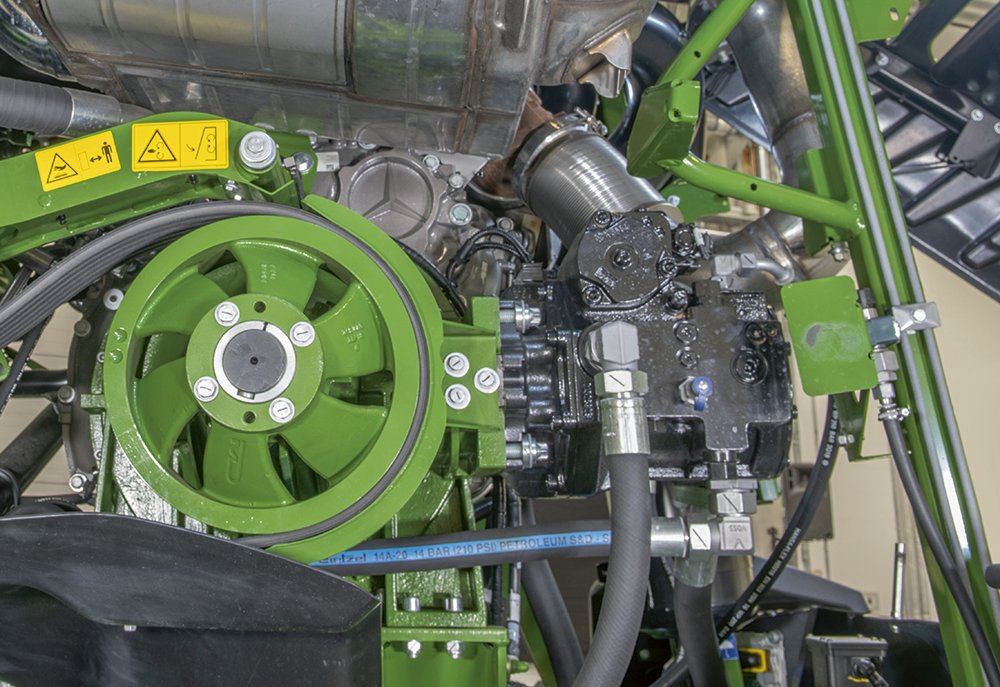

The transversely mounted engine allows the drive pump, the chopping drum, the crop accelerator, the header and intake pumps to take the engine power directly off poly V-belts. No power take-off gear is required. All components for crop flow are activated via belt coupling. |

Clever: The header and intake system are driven by oil pumps. Flange mounted to a gearbox, these pumps are driven by a separated poly V-belt that transmits engine power directly to the pumps. This concept allows for infinite adjustment of header and intake speeds. |

CVT transmission: Courtesy of a hydro pump that is flange-mounted on the main gearbox, BiG X changes its ground speed infinitely variably. |

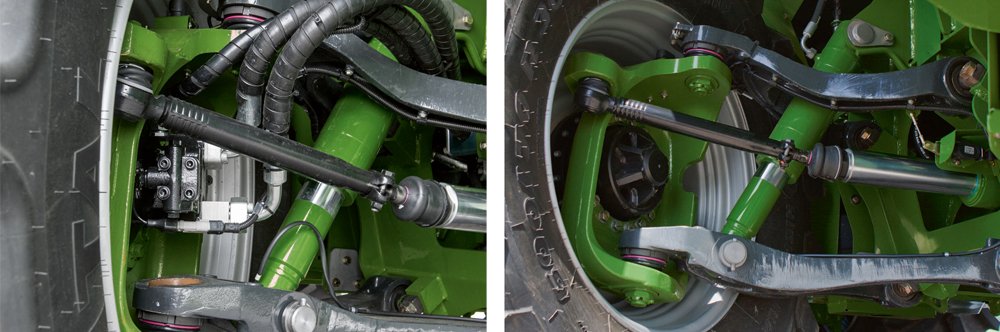

The hydrostatic wheel motors offer greater productivity and a higher level of automation and operator convenience. At the same time, this type of power train reduces maintenance and frees valuable space to fit a bigger and more powerful chopping assembly and move this further to the rear of the machine. |

Front-wheel drive – four-wheel drive: BiG X 480, BiG X 530, BiG X 580 and BiG X 630 are available with optional hydraulic four-wheel drive via wheel motors. Machines with front-wheel drive have hubs on the rear wheels instead of wheel motors. Both drive trains are designed for speeds of up to 40 km/h. |

Planetary gearbox: The wheels are driven by Bosch planetary gearboxes. Planetary gearboxes offer the advantage of distributing the load to several planetary wheels which are compact and enable high torques. |

A KRONE exclusive! The wheel motors are mounted eccentrically on the front axle which allows you to fit small or large tyres and still retain the position of the pick-up, the intake system and chopping drum floor relative to the downstream crop flow. This detail warrants an optimum and consistent crop flow. |

Superb manoeuvrability: The use of wheel motors allows the wheels to turn through 50° for tightest turns and perfect match-ups after headland turns with an 8-row maize header. |

Tyres with a purpose: The BiG X 480, 530, 580 and 630 can be fitted with up to 900/60 R 42 tyres. The massive tyres guarantee maximum ground clearance, smallest ground pressure and ultimate operator comfort. |

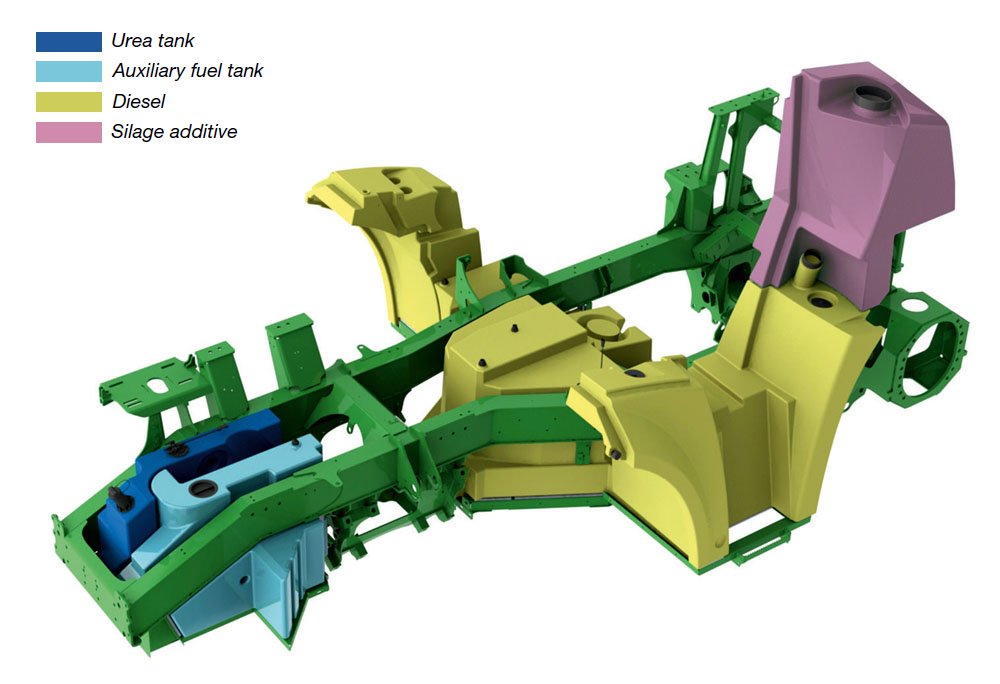

Long working days, sometimes even deep into the night, take a toll on the operator's endurance and concentration. This obviously requires excellent all-round visibility and full illumination at night, which is exactly what BiG X offers. The up to 1,450-litre fuel tanks hold enough diesel reduce the number of time-consuming top-ups and boost productivity Optimum access to all components ensures trouble-free service and maintenance. |

Turns the night into day: 16 headlights for optimum illumination make night work easier and safer. If you who want even more light you can opt for the LED lighting kit. |

Up to 1,450 litres of diesel on board: The huge fuel tank provided as a standard holds up to 1,220 litres of diesel. An additional tank holds 115 litres of urea. The result are many hours of work without interruption for fuelling up. In addition to that, you can also opt for a 230l fuel tank and a 275l silage additive tank. |

Panoramic view: The hoods open wide and the rear mudguards give perfect access to all assemblies. LEDs are in place for easy service and maintenance even in poor light conditions. |

Plenty of room: There’s plenty of room between the cooling system and the crop flow on the BiG X 480, 530, 580 and 630 models, giving easy access to all components for cleaning and maintenance. |

New premium cab developed to the latest ergonomic insights Providing generous space and an extra seat, it offers a fully air-conditioned and absolutely functional working place, where the operator feels at home and has full command of all functions and controls. |

Wider, quieter and brighter: The wide and slim posted cab offers plenty of space and best view of the headers with wide working widths. The double floor gives effective insulation from noise. 14 halogen head lights and work lights or 17 LED lights as an option provide perfect illumination in any situation and make your job easier in poor light conditions. |

Clear view all-round: No matter the conditions – rain or dust –BiG X operators always enjoy a clear view thanks to three optional wipers on the front window, two on the side windows and one on the rear window. All wipers have spray nozzles for optimum cleaning. |

Ergonomic, convenient, good: The ergonomic shape of the multi-function lever with its user-friendly icons makes work easier and increases the operator comfort. Designed specifically for the BiG X, it fits the hand nicely. With more than 20 functions programmed to it, the lever not only controls driving speed and direction of travel but also the header and spout. |

Keeping you informed: An 8” touch colour touch screen with USB and camera ports is standard specification on the BiG X (12” as an option). The terminal logs all major machine and harvest data and displays the camera feeds from the spout and rear end. Here you enter all kinds of settings including the infinitely variable chop length. |

AutoScan: The photo-optical sensor in the middle of the maize header records the degree of maturity of the maize plant and ensures that the chop length is adapted automatically. For better structure and less silage effluent in the silo, the chopping length for green maize is longer. For dry maize, however, a shorter chopping length is used for better compaction in the silo. AutoScan eases the strain on the operator and saves fuel because the plants are cut only as short as necessary, no longer as short as possible. In KRONE machines, AutoScan is the standard, not an expensive extra equipment. |

ConstantPower: ConstantPower automatically adjusts the machine‘s ground speed to the engine loading. Select the desired engine loading at the touch of a button and the machine will adapt its ground speed fully automatically to the crop and material being harvested. This standard feature reduces operator stress and ensures maximum throughputs with minimum fuel consumption. In combination with AutoScan, this system takes the overall quality of chop and machine performance to a whole new level. |

EasyLoad: The EasyLoad auto loading system in combination with a camera-based 3D image analysis system allows operators to fill any type of trailer that is running alongside the harvester. The system controls the "open/close spout" and the "rotate left/right functions" and allows operators to select one of several filling strategies. Monitoring all functions from the in-cab screen, operators are more at ease. |

RockProtect: The six pre-compression rollers are powerful yet gentle. The optional RockProtect system provides intelligent protection from damage by stones. It fully automatically halts the pre-compression rollers within milliseconds after a stone is detected. The sensitivity of the RockProtect system is adjustable for added protection. |

ISOBUS steering system: As an option, every BiG X machine is ready to accept various ISOBUS guidance systems from different manufacturers. On the move, the operator activates autoguidance from the KRONE joystick. simply by pressing a button and then watches how the system guides BiG X down the bout. Automatic steering makes work easier for the operator and increases acreage output even with broad spreading, thereby increasing performance. |

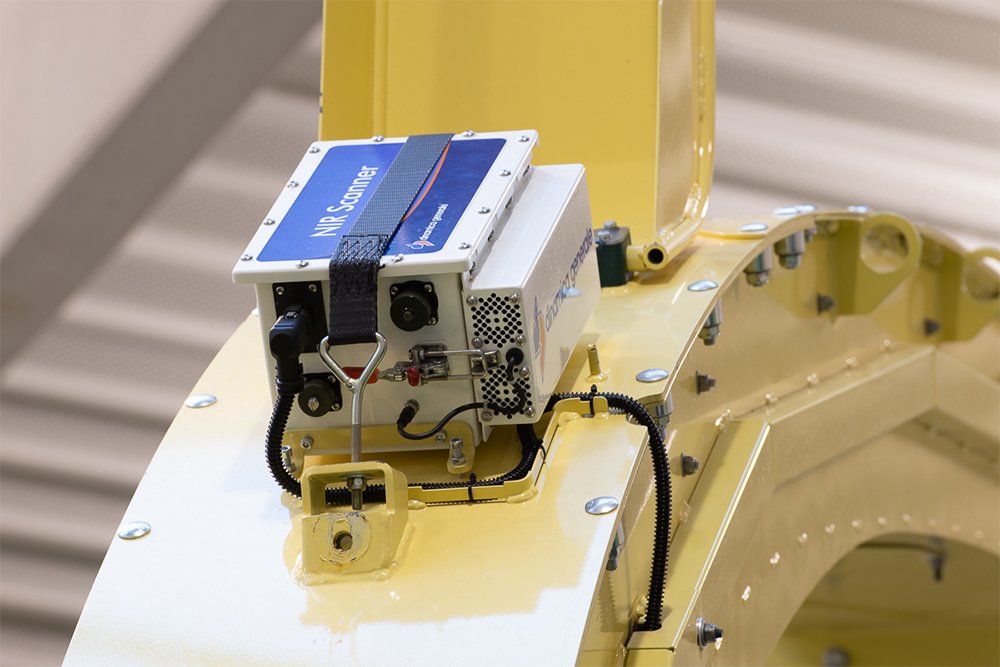

Metering moisture and nutrient levels: The optional AgriNIR online sensor supplies accurate data on moisture and nutrient levels on the move (DS, starch, crude protein, crude ash, crude fat, ADF, NDF). This data can be recorded in the machine terminal and assigned to the harvested area. The AgriNIR online sensor is easy to install on the BiG X spout where it is protected from damage by a cover. |

CropControl: The optional KRONE CropControl yield metering system measures the volume of crop harvested quickly and accurately at the touch of a button. With CropControl you can seamlessly document yield information on all fields harvested. |

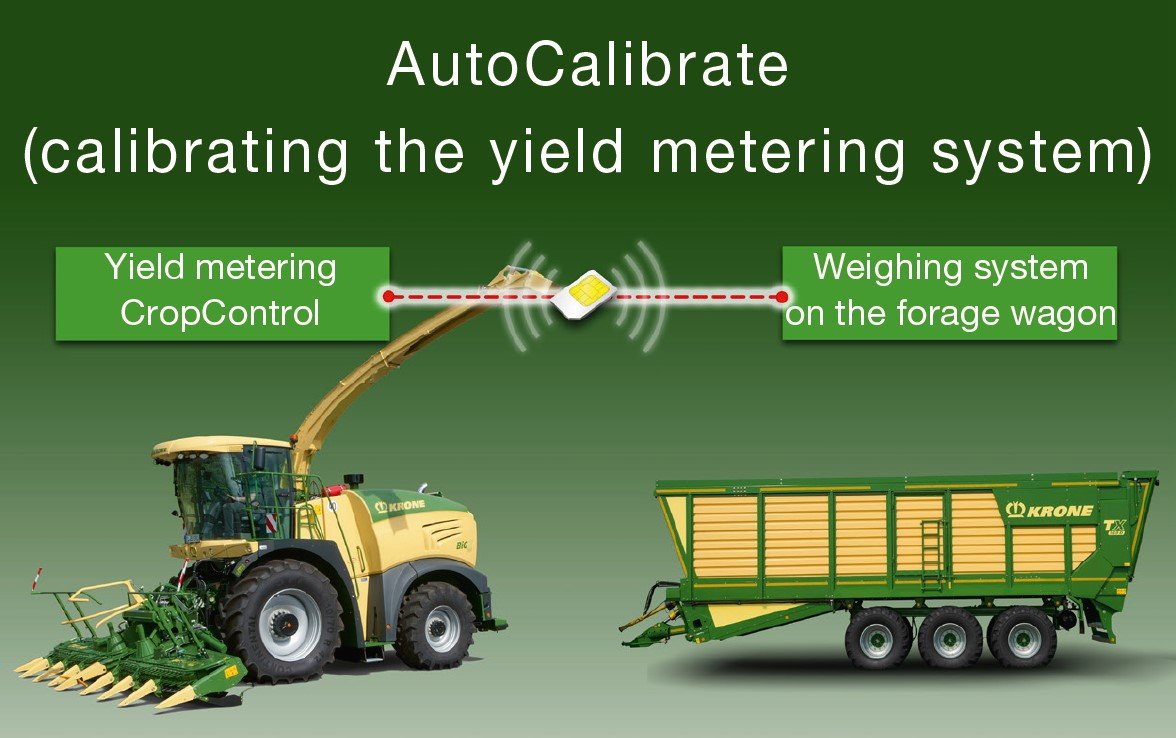

Convenient weighing: AutoCalibrate is the remote calibration tool for the BiG X‘s yield recording system. It operates via a weighing device installed on one of the trailers in the harvest fleet. Both the BiG X and the trailer are equipped with data loggers that communicate via a mobile network. Calibration takes place in real time as the ‘calibrating machine’ is being filled. AutoCalibrate is highly accurate and is the first system of its kind to eliminate the trip to the weighbridge. |